The Tyranny of Time Series

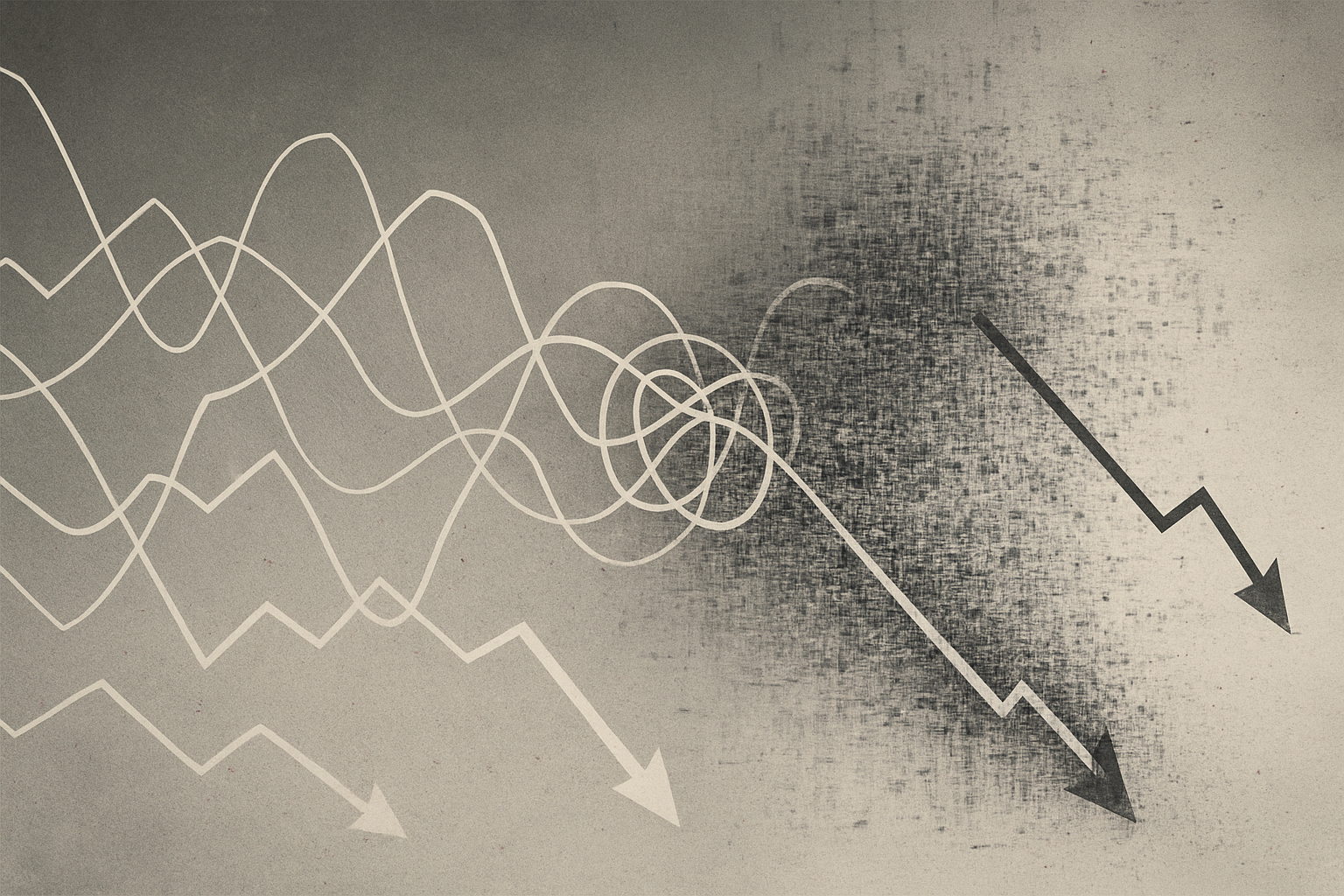

Few mathematical abstractions have hurt supply‑chain performance as pervasively—and as quietly—as the humble time‑series. In spite of this track record, time‑series remain fashionable. Entire software categories are built around time‑series storage, analysis, and forecasting; planning frameworks such as S&OP or IBP are articulated almost exclusively through them; and most academic syllabi treat the study of supply chains as little more than an exercise in composing, decomposing, and extrapolating time series.

But popularity does not confer validity. At Lokad we walked away from the time‑series paradigm more than a decade ago because it systematically ignores the very forces that shape modern supply chains. By reducing everything to a single chronological dimension, it blinds practitioners to the multi‑layered interactions among customers, products, suppliers, and constraints. What follows is a tour of the blind spots that inevitably emerge when time series becomes the one‑size‑fits‑all lens for decision‑making.

1. Time‑Series and the Vanishing Customer

Many textbooks—and therefore much commercial software—assert that customers perceive “service quality” through numeric service‑level targets (e.g., “95 % availability”). Translating the messy reality of customer experience into a neat time series of fill‑rates may be convenient, but it is also demonstrably false.

Baskets

Customers buy baskets, not isolated SKUs. The absence of a single item can cause the entire transaction—and possibly the customer relationship—to evaporate. Because a time‑series stores quantities and dates stripped of transaction context, it cannot reconstruct which items were supposed to travel together, which substitutes were offered, or how the customer reacted. The data structure is, by design, customer‑blind.

Loyalty

Most businesses depend on repeat purchases. Whether you sell fashion apparel or industrial fasteners, nurturing a loyal customer base is mission‑critical. Yet the classic time series discards the buyer’s identity as soon as the invoice posts. It cannot detect that a first‑time buyer became a brand advocate, nor that a disappointed regular quietly defected to a competitor. Once again the decisive signal is lost.

Substitutions and Cannibalizations

Customers often have latitude in how they satisfy a need: they will trade size, color, brand, or pack‑size for immediacy or price. Modeling such choice dynamics requires observing which alternative the customer selected when the preferred item was unavailable. The traditional time series, limited to “demand for SKU X on day D,” is structurally incapable of encoding that choice.

In short, framing “service quality” as a time series of service levels erases almost everything that matters to the customer.

2. Time‑Series and the Invisible Supplier

The limitations of the time‑series lens are symmetrical: it obscures supplier realities as effectively as it erases those of the customers we try to serve.

Lead‑Time Entanglement

Treating lead time as an independent time series per SKU assumes that each purchase order arrives in an isolated vacuum. In practice, large orders consume supplier capacity, lengthen subsequent lead times, and precipitate cascading delays. Capacity coupling is a multi‑dimensional phenomenon; it cannot be understood—let alone optimized—when every item is pigeon‑holed into its own timeline.

Batching Economics

Purchasing is rarely about finding the “optimal quantity” for each SKU in isolation. The real game is synchronizing hundreds of SKUs into economic truckloads, container loads, or production runs. The canonical EOQ formulation, born of the time‑series mindset, ignores cross‑SKU synergies and thus misses the point entirely.

Shared Value Creation

The most valuable suppliers are co‑innovators: they suggest design tweaks, propose new assortments, and share risk. Such collaborative dynamics evolve over quarters and years, not in a neat periodic rhythm. By forcing reality into stationary series, the analyst renders supplier innovation literally invisible.

3. The Comfort of an Inward‑Looking Paradigm

Why, then, does the time‑series paradigm persist? Because it is easy.

-

Academia adores time series: they yield elegant autoregressive models that are simple to lecture about, simple to assign as homework, and simple to grade.

-

Software vendors adore time series: storing data as a timestamp plus a number is trivial, as is bolting on a forecasting widget to extrapolate the curve.

-

Managers adore time‑series dashboards: a tidy line graph offers the comforting illusion that the past made sense and the future will differ only marginally.

But convenience is not capability. An inward‑looking company may convince itself that these curves measure performance; the market, unburdened by the illusion, will still punish poor allocation of stock, capacity, and cash.

4. Breaking Free: Embracing High‑Dimensional Reality

Since the late 1990s, advances in high‑dimensional statistics, probabilistic programming, and large‑scale optimization have made it perfectly feasible to model the real, messy shape of supply chains: transactions, baskets, options, constraints, and feedback loops. Yes, the resulting models are more complex than a univariate time‑series—but the extra complexity is not a vice; it is the irreducible complexity already present in the business itself.

Lokad’s own predictive‑optimization stack has often been called “complicated.” We plead guilty, with one caveat: our methods mirror the pre‑existing intricacy of retail, manufacturing, aviation, or oil & gas. Retail would be trivial if every product fought for shelf space in splendid isolation. Manufacturing would be trivial if production orders never competed for shared machines or raw materials. International logistics would be trivial if containers magically resized themselves. Reality refuses to be so obliging; pretending otherwise through time‑series sophistry only compounds the cost.

5. Conclusion

Time‑series analysis is not wrong; it is simply insufficient. Like a two‑dimensional map of a mountain range, it can be useful for certain narrow tasks, but disastrous if relied upon for navigating the terrain. A modern supply chain lives in a space where customers, products, suppliers, capacities, and constraints interact in ways a single timeline cannot encode.

Sticking to time series because they are easy is an abdication. The tools now exist to confront supply‑chain complexity head‑on, and the competitive edge they confer is growing every quarter. The question is no longer whether we can transcend the tyranny of time series, but whether we dare to build organizations that choose insight over convenience.