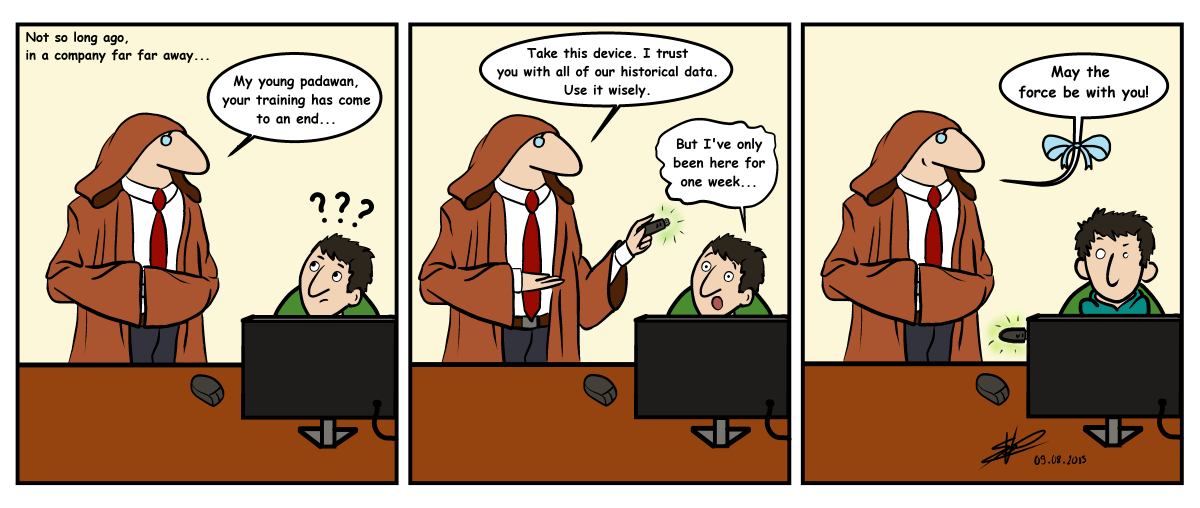

The Jedi Initiation (Supply Chain Antipattern)

Remember the story of a young man that was supposed to take over an evil space empire after a couple of botched training sessions which primarily involved blindfolded sword fighting while the task at hand was the destruction of a spatial megastructure? Well, despite the teachings of popular space operas, it is not advised to entrust the most important business challenges to interns.

Category: management

Alias: we trust our interns!

Category: management

Problem: the company is large and mature. Supply chain processes are working relatively smoothly. One decade ago, these processes would have been considered as, maybe not best practices, but good practices. However, competition has taken a leap forward, and supply chain management seems to be falling behind. Replenishment timelines, inventory levels and quality of service observed in the past are no longer tenable. New technologies and new methodologies have resulted in big opportunities for improvement, and such opportunities have not gone unnoticed by the company’s Board of Directors. As a result, the Board tasks the CEO with implementing a new technology initiative, who then forwards the case to the VP of Supply Chain. In turn, the VP sends the case to the Supply Chain Manager, who, having his hands full already, delegates the case to a new intern. One year later, the initiative has been loosely passed on from one intern to the next. A few pilot studies have been conducted with vendors, with each study extensively involving the IT department, but nothing conclusive is emerging. The initiative is picked up by a couple of more interns joining the company before finally being dismissed by the upper management.

Anecdotal evidence: interns or junior employees are often found getting in touch with tech vendors in order to find a solution to their company’s supply chain challenges. The solutions proposed by the vendors are often worth over 100 times of the intern’s annual salary if the found solution actually becomes implemented. At the same time, the solution probably also costs well over 100 times the intern’s yearly salary if the said solution fails in production.

Context: the company in question is mature and its processes are relatively lean for a company of its size. Top level executives do not have the time to be hands-on with operational projects, and neither do they have the time to figure out the ins and outs of the myriad of new technologies that could improve every aspect of their supply chain. In a similar vein, middle management is also highly occupied by operational processes and hardly has any spare time on its hands. Also, since supply chain management is considered to be a cost center for the company, headcount is nearly frozen for this part of the organization. Exceptions can be made, but middle management prefers to only use this option as a back-up plan for real operational emergencies, without getting involved in any new risky approaches.

Supposed solution: The “push” for implementing a new technology initiative comes from the top, but down the line, the Supply Chain Manager already has his hands full with other day-to-day tasks. Also, he does not have the authority to hire someone to take care of this project. Worse still, as the issue in question is complex and technical, it would probably take someone with more seniority and expertise than that of the Supply Chain Manager to really get any results. Thus, instead of hiring a more senior employee, the Manager takes on an intern (with no impact on the headcount) and makes him responsible for the whole thing. The intern is smart and enthusiastic, and may even have better academic credentials than his Manager. The Manager and his boss agree that this is worth a try.

Resulting context: The intern has close to zero experience with the problem at hand. Like with most technologies, even a simple assessment of the issue in question requires the involvement of many different parties within the same company. The Supply Chain Manager himself would barely have enough authority to get the necessary attention from all the relevant parties within the company. For the intern however, this is simply impossible. As a result, the intern falls back on talking with the technology vendors, who are always willing to spend more and more time conversing with their prospect. However, the intern is barely aware of all the company’s requirements and processes, and hence, cannot even guide the vendors in making an effective sales proposal. The intern cannot really assess if any of the solutions proposed by the vendors would actually have any value for the company. Since working with some sort of numbers makes the task on hand to be perceived as more “scientific”, the intern may come up with some measurements, maybe even a benchmark. However, the benchmark is likely to significantly overemphasize certain aspects of the business, while entirely ignoring other important ones. When managements steps in, typically months later, the major gaps are identified and the work gets trashed. The intern leaves, and the company is back to the starting point.

Seductive forces: The Supply Chain Manager gets tasked with the challenge described above, but without hands-on support from his hierarchy. The intern costs almost nothing to the company and does not have an impact on the headcount either. In addition, the management feels a bit overwhelmed by the sheer technicalities involved in adopting a new approach to an old problem. Current manual processes may be crude, but they are perceived as very “manageable”. In contrast, newer approaches involve a fair share of engineering and number crunching, which makes most of the management feel rather uneasy. Because the newly hired intern has just recently graduated with a modern supply chain degree - which places a lot of emphasis on technical engineering skills applied to supply chain management – the management thinks that this will give a big boost to the initiative.

Why this leads to failure: Nearly all new supply chain technologies cannot just merely “improve” the company’s processes, they also need to transform the company if any benefit is to be observed from adopting such an initiative. However, rolling out a new technology, even if the technology has a limited impact, requires every company to redefine its status-quo. Collecting all the relevant information necessary for the implementation of the new project typically goes well beyond the degree of autonomy that an entry position can usually provide. Moreover, even if the intern (or junior employee) has sufficient charisma to work his way through the organization in order to carry out reasonable analysis relating to the technology in question and how it should be rolled out, the intern will subsequently not have the power to execute the plan. As the plan will invariably disturb the routine of at least a few people, the intern will be expected to face downright opposition from authorities greater than his own. His manager could help out with this, but since he was too busy to carry out with the investigation himself in the first place (this is why the intern was hired), dealing with other parts of the organization represents an even more time-consuming challenge for this manager. Not even mentioning that he would have to defend the technical grounds of the project, which will feel as somewhat of a dreadful task. The management is under the delusion that it is possible to roll out new technologies without being very hands-on and fully committed to the initiative.

Positive ways of addressing the problem: smart and enthusiastic interns can deliver results, but they require top level executive attention and support for two reasons. First, to protect them from petty company politics; and second, to give them the necessary high-level strategic inputs allowing them not to get side-tracked by technicalities and problems that are complex but that have well-known solutions. However, in order to succeed, a company needs interns who are likely to have the capacity to be employed by top management consulting firms; not your “average” intern. In practice, a more realistic approach involves reprioritizing the tasks carried out by top management, choosing more wisely the battles to be fought internally, and to ensure that the chosen initiatives are executed in a hands-on matter. In particular, if all levels of management - all the way down from the CEO to the Supply Chain Managers - are so busy that they cannot take on anything apart from their most mundane routine tasks, then this means that the company is indeed stuck in its current processes without any room for improvement. The upper management needs to reassess what it is that is actually keeping all the management layers busy in order to figure out how to recover flexibility.

Example: Contoso is a large food retail chain. Reducing the frequency of out-of-shelf issues has been a long-standing problem for the business. The company’s objectives, including selling fresher products with a greater shelf-life and increasing the diversity of products to attract more diverse customer segments, is only making the problem worse. The issue can be tackled from many, many different angles: stock-counting processes can be improved, basic hardware can be improved, replenishment can be improved, and so on. Some solutions are pure hardware, some are pure software, some are a mix of hardware and software, and all solutions require modifying the existing processes to some extent.

The Board decides that they want to increase customer loyalty in order to consolidate their market share. Reducing out-of-shelf issues is a key problem as this is one of the main reasons that incites otherwise loyal customers to give their preference to a competing retail chain. The CEO is tasked by the Board to address this challenge, and the CEO quickly passes on the case to the Head of Supply Chain. For the Head of Supply Chain, the topic is not new: it has been brought to the table just about every year for the last decade. The processes relating to these issues have been improved already, but there are limits as you cannot really prevent customers from entering your store just for the sake of not messing up your inventory. The IT processes have also been improved and they are now reasonably accurate and reliable, albeit a notch too expensive. But reducing IT costs is not risk-free, and this is unlikely to help as far as out-of-shelf problems are concerned in any case.

Consequently, partly for a lack of better ideas, the Head of Supply Chain delegates the case to one of his Supply Chain Managers. This Manager is already the one who is coordinating most methods and supply chain processes, so he is probably the best-placed “expert” available to the company. In addition to this, the Supply Chain Manager is also quite familiar with the challenge in question. Over the years, he has actually implemented many small initiatives, some of them bringing small but measurable gains, as far as out-of-shelf issues were concerned. However, at this point, to make further progress, the solutions that could potentially be implemented by the company would require a heavy dose of electronics or software, or even both. And this is something that the Supply Chain Manager never considered as part of the core skills of his supply chain activity. Also, while the company is paying decent salaries for its office jobs, the company is very uncompetitive on the marketplace. First, new graduates with strong software or electronic engineering skills are high in demand and tend to request salaries that go well beyond what the company usually offers for entry positions. Second, for this type of employee profile, it is quite difficult to compete with other more “prestigious” employers, like banks, management consulting firms or multinational technology companies.

However, the company does manage to attract talented interns once in a while, partially because the remuneration gap between intern pay offered by the company and the pay they can obtain interning at “prestigious” companies is much less pronounced compared to the entry level salaries for full-time positions. However, as a consequence, even when the company’s headcount policies allow it, these interns rarely stay in the company at the end of their internship.

The manager manages to hire Jake, a 22 year old student who is currently studying for a very decent supply chain Master program. Jake is going to join the company for the duration of 6 months, and his only mission will consist of finding solutions aimed at improving the company’s out-of-shelf problems for a nationwide retail network spanning over 1000 stores. As Jake’s manager is very busy and can only offer little actual guidance beyond scoping the problem, Jake is mostly on his own starting from Day 2 (Day 1 was entirely consumed by mundane corporate tasks).

Jake quickly identifies a series of vendors selling pressure measurement hardware for shelves, which could provide real-time data on stock availability. On paper, this looks like the perfect solution for the problem. So Jake spends a few weeks speaking to various vendors over the phone to learn more about the different solutions available. All solutions require some degree of IT integration, and Jake spends days on end trying to get relevant information out of the IT team. The company’s IT department is actually more functional than most, hand yet, they still have a heavy roadmap to roll-out, and nobody wants to spend much time coaching an intern on a mission that is completely unaccounted for as far as planning is concerned. However, Jake keeps pushing and finally manages to extract a few nuggets of information out of the team. Yet, since this is Jake’s first time trying to gather some relevant observations relating to the enterprise IT systems, the information he manages to put together is very partial, and does not even address the questions of the tech vendors with whom Jake is in touch.

6 weeks later, once a sizeable amount of materials has been gathered, Jake can finally get some attention from his manager to review all of the documents that he had put together, and a meeting with other stakeholders is organized to review this material. Two weeks on, the first big meeting is taking place for Jake. However, things fall apart immediately. Within the first quarter of an hour into the meeting, the Head of Supply Chain realizes that the tech vendors with whom Jake is in touch have already been tested by the company 5 years ago, just before Jake’s manager arrived actually. Some vendors now have different company names (often due to acquisitions), but the fundamentals remain the same: their technology works but is too fragile for the rough store environments and the cost of maintenance is too high. The bottom line is - it is not worth it. The Head of Supply Chain could have mentioned this to Jake on Day 2, but him and his subordinates barely had the time to keep up with their routine work, let alone keep track of additional “loose” initiatives within their department. The Supply Chain Manager did mention a couple of vendors’ names to the Head of Supply Chain, but given that most of the names had changed, the Head of Supply Chain did not realize that they were re-investigating the same dead end once again. Tech vendors are good at making old stuff look brand new.

Back to the starting point, Jake decided to take another angle and to investigate the “pure” software solutions this time around. However, to make sure that the solutions were suitable for the business, and to avoid losing face in front of his boss (as well as the boss of his boss) for a second time, Jake decided that he would now test the solutions by himself beforehand. Unlike the hardware solutions which were really straightforward to understand, Jake was now dealing with products that felt really abstract. Most of them relied on advanced data analytics, the gist of which was quite beyond the 20-hour course that Jake did as part of his “Programming and Data Analysis” class the semester before.

Jake decided to gather real data to carry out a test. This was easier said than done. Once again, Jake had to go through IT, and once again, the IT department was not prepared to allocate their already limited resources towards a “random” initiative. After weeks of effort, Jake finally “cracked” the problem by using the login and password that has been handed over to him by his boss (obtaining his own access credentials to the company system would just have taken forever), and finally managed to get his hands on various Excel extracts. Since Excel could only extract 20,000 lines at a time, even the smallest “meaningful” data extraction involved dozens of sheets.

The data extraction turned out to be a very lengthy and tedious process, but this was nothing compared to the process involving the software vendors. They had too many questions about the data that Jake was not able to answer, and every single Excel column triggered questions and concerns. Then, Jake realized that each vendor was delivering results in such a way that they could not be compared with the results provided by the other vendors. However, considering that all the vendor solutions examined by Jake were adopting, from the beginning, very different methods when compared with each other, this outcome was not completely unexpected.

Near the end of his internship, Jake had another big meeting with the Head of the Supply Chain. It went a bit better this time, at least as far as Jake was concerned. However, the Head of Supply Chain pointed out that none of the solutions identified by Jake were taking into account the varying stock-out costs for the different individual product items. However, no matter what type of optimization was to be implemented via any the analytics solutions chosen by Jake, the company needed to prioritize their product items based not only on their cost and margins, but also on the propensity of their stock-outs to result in customer churn. Jake had indeed assessed many aspects of the problem at hand, but he had completely neglected this facet of the issue, largely invaliding all supposed findings.

The materials gathered by Jake stayed on his manager’s desk for the next few months, before finally being trashed as the manager moved on to a new position. Several years following the end of Jake’s internship, and a couple of other interns later, the company has not yet made any progress as far as out-of-shelf issues are concerned.