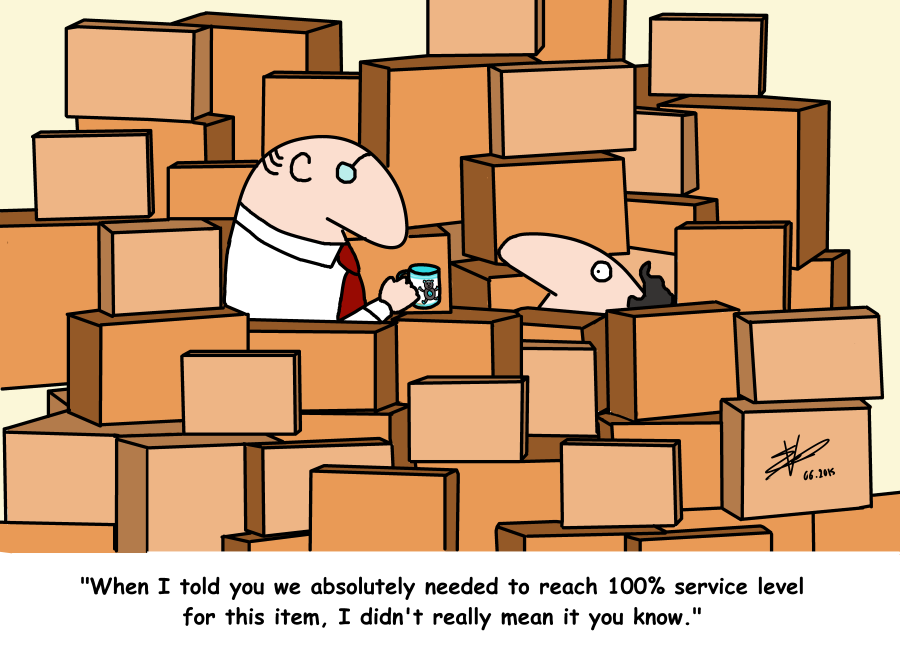

The 100% Service Level (Supply Chain Antipattern)

Why would you settle for doing something well when you can achieve perfection?

Category: management

Achieving a 100% service level, in order words, 0% of stock-outs or delays, is a fantasy that is unfortunately still chased by too many companies. From a purely mathematical perspective, as future demand is uncertain and unbounded, achieving a guaranteed 100% service level would require an infinite amount of inventory; which is hardly tractable.

Fundamentally, inventory optimization is a trade-off between the cost of inventory and the cost of stock-outs. No matter what forecasting method is used, the result is the same: nothing short of infinite inventory can mathematically guarantee zero stock-outs.

When dealing with such situations, it’s important to put a price tag on stock-outs - possibly a very high price tag if it makes sense from a business perspective - and to start balancing the costs. As extra inventory brings diminishing returns, an equilibrium needs to be found to optimize the return on investment (ROI) for your company, but it won’t be at 100% service level.