Optimizing inventory with kits or bundles

Merchants are frequently selling kits (or bundles), where several items are sold together, while the possibility remains to buy the items separately. The existence of kits further complicates inventory optimization because it introduces dependencies between items as far availability is concern. In this post, we try to shed some lights about optimizing inventory in presence of kits.

There are two opposed approaches to deal with kits:

- Do not store any kits, only separate items. Assemble the kits at the last moment assuming that all items are available.

- Store all kits pre-assembled as a separate SKUs. Kits are assembled in advance. If no kit is readily available, the kit is considered as out-of-stock.

In practice, most inventory policies toward kits tend to be a mix of those two approaches.

Let’s start the review with the first approach. The primary benefit of keeping everything disassembled is that it maximizes the availability of the separate items; however, this comes at the expense of the kit availability.

Indeed, assuming the availability levels of items are independent and refered with L1, L2, … Lk (for a kit with k items), then the availability of the kit LK = L1 x L2 x … x Lk.

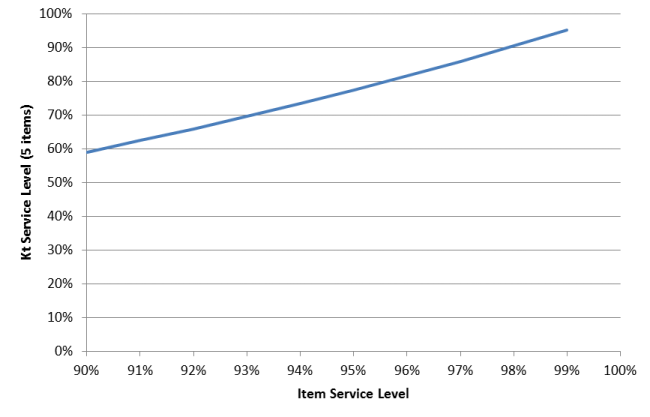

Let’s assume that we have a kit with 5 items, all items having the same service level. The graph above illustrates the correspondence between the service level of the kit w/o of the service levels of the separate items.

For example, with 5 items at 90% service level, the kit ends up with a service level slightly below 60%. This behavior illustrates weakest link behavior of kits: it only takes one item to be out-of-stock to put the whole kit out-of-stock. Even if all items have fairly high availability, the kit availability can be much lower; and the bigger the kit, the worse it gets. If instead of 5 items, we consider a kit with 10 items at 90% service level, then the kit service availability is reduced to 35%; which is typically unacceptable for most businesses.

The second approach consists of storing pre-assembled kits. This approach maximizes the availability of kits. In this case, kits are treated as like any other item: the demand for kits is forecast, with quantiles forecasts, and a reorder point is computed for the SKU representing the kits. This inventory policy preserves a strict decoupling of the kit and its items.

With this approach, the service level of the kit is driven by the quantile calculation. As such, the kit is not negatively impacted by the separate availability of the items. Each item also gets its separate reorder point.

The primary drawback of this second approach is that, in the worst case, the amount of inventory can be doubled for limited or no extra availability. In practice however, assuming that about half of the item consumption comes for kit’s sales, the stock is typically increased by roughly 50% when applying this second approach instead of the first one; the extra inventory is used to ensure the high level of availability of the kit itself.

The optimal inventory strategy, the one that maximizes the ROI (Return On Inventory), is usually a mix of those two approaches.

The exact inventory optimization of kits is a relatively intricate problem, however the problem could be rephrased as: at which point should the merchant start refusing to sell separately one of the kit’s items because she would risk losing more advantageous orders on kits instead?

Indeed, all long as kits are available, there is typically no incentive for the merchant to refuse selling a kit in order to preserve the availability of the separate items. (There might be an incentive if items have much higher gross margin than the kit, but for the sake of simplicity, this case is beyond the scope of the present discussion).

In order to determine how many items should be preserved for kits (assembled or not), one can use an alternative quantile forecasts, where the service level is not set as a desired availability target, but on a much lower probability that reflects a probable sales volume that should be preserved.

For example, let’s assume that a 30% service level on a kit gives a quantile forecast at 5. This value can be interpreted as “there are 70% chances that 5 or more units of the kits will be sold over the duration of the lead time”. If a 70% confidence in selling 5 kits outweighs the benefits of selling the next item now (assuming only 5 items remain), then the item should be considered as reserved for kitting purposes.

We are still only scratching the surface as far kits are concerned. Don’t hesitate to post your question in comments.

Reader Comments (2)

Can you elaborate on a scenario where the individual parts that make up a kit or bill of materials are not sell-able by themselves? 5 years ago | William Davidson

In theory, parts are always sell-able by themselves. However, there are situations where it makes little sense. For example, IKEA could try to sell its furniture’s without the hexagonal screw drivers normally bundled in every package, charging $0.20 less in this case. However, not only the demand is too low to justify such extra supply complexity, it would also confuse many customers. 5 years ago | Joannes Vermorel