Supply Chain Lectures

BACK TO LOKAD TV ›

On Knowledge, Time and Work for Supply Chains - Lecture 1.7

Supply chains abide by the general economic principles. Yet, these principles are too little known and too frequently misrepresented. Popular supply chain practices and their theories often contradict what is generally agreed upon in economics.

Pricing Optimization for the Automotive Aftermarket - Lecture 6.2

The balance of supply and demand very much depends on prices. Thus, pricing optimization belongs to the realm of supply chain, at least to a sizeable extent. We will present a series of techniques to optimize the prices of a fictitious automotive aftermarket company. Through this example, we will see the danger associated with abstract lines of reasoning that fail to see the proper context. Knowing what ought to be optimized is more important than the fine print of the optimization itself.

The Supply Chain Scientist - Lecture 7.3

At the core of a Quantitative Supply Chain initiative, there is the Supply Chain Scientist (SCS) who executes the data preparation, the economic modeling and the KPI reporting. The smart automation of the supply chain decisions is the end-product of the work done by the SCS. The SCS takes ownership of the generated decisions. The SCS delivers human intelligence magnified through machine processing power.

Lead-time forecasting - Lecture 5.3

Lead times are a fundamental facet of most supply chain situations. Lead times can and should be forecast just like demand. Probabilistic forecasting models, dedicated to lead times, can be used. A series of techniques are presented to craft probabilistic lead time forecasts for supply chain purposes. Composing those forecasts, lead time and demand, is a cornerstone of predictive modeling in supply chain.

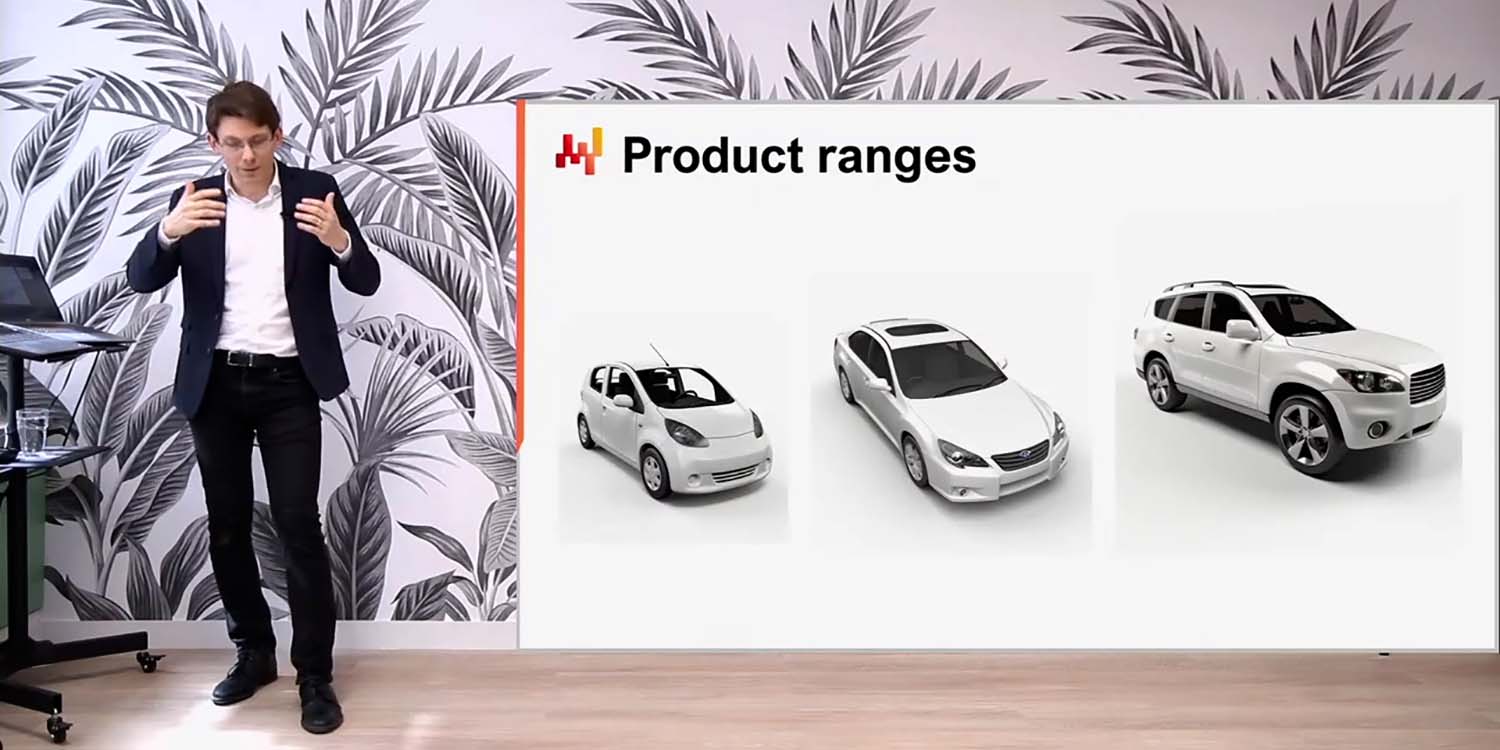

Supply Chain Persona: Stuttgart, an automotive aftermarket company - Lecture 3.4

Stuttgart is a fictitious automotive aftermarket company. They operate a network of stores delivering car repairs, car parts and car accessories. In the early 2010s, Stuttgart also started two ecommerce channels, one to buy and sell car parts, and one to buy and sell used cars.

Bringing automated supply chain decisions to production - Lecture 7.2

We seek a numerical recipe to drive an entire class of mundane decisions, such as stock replenishments. Automation is essential to make supply chain a capitalistic endeavor. However, it carries substantial risks of doing damage at scale if the numerical recipe is defective.

Getting started with a quantitative supply chain initiative - Lecture 7.1

Conducting a successful predictive optimization of a supply chain is a mix of soft and hard problems Unfortunately, it is not possible to take those aspects apart. The soft and hard facets are deeply entangled. Usually, this entanglement collides frontally with the division of work as defined by the organigram of the company.

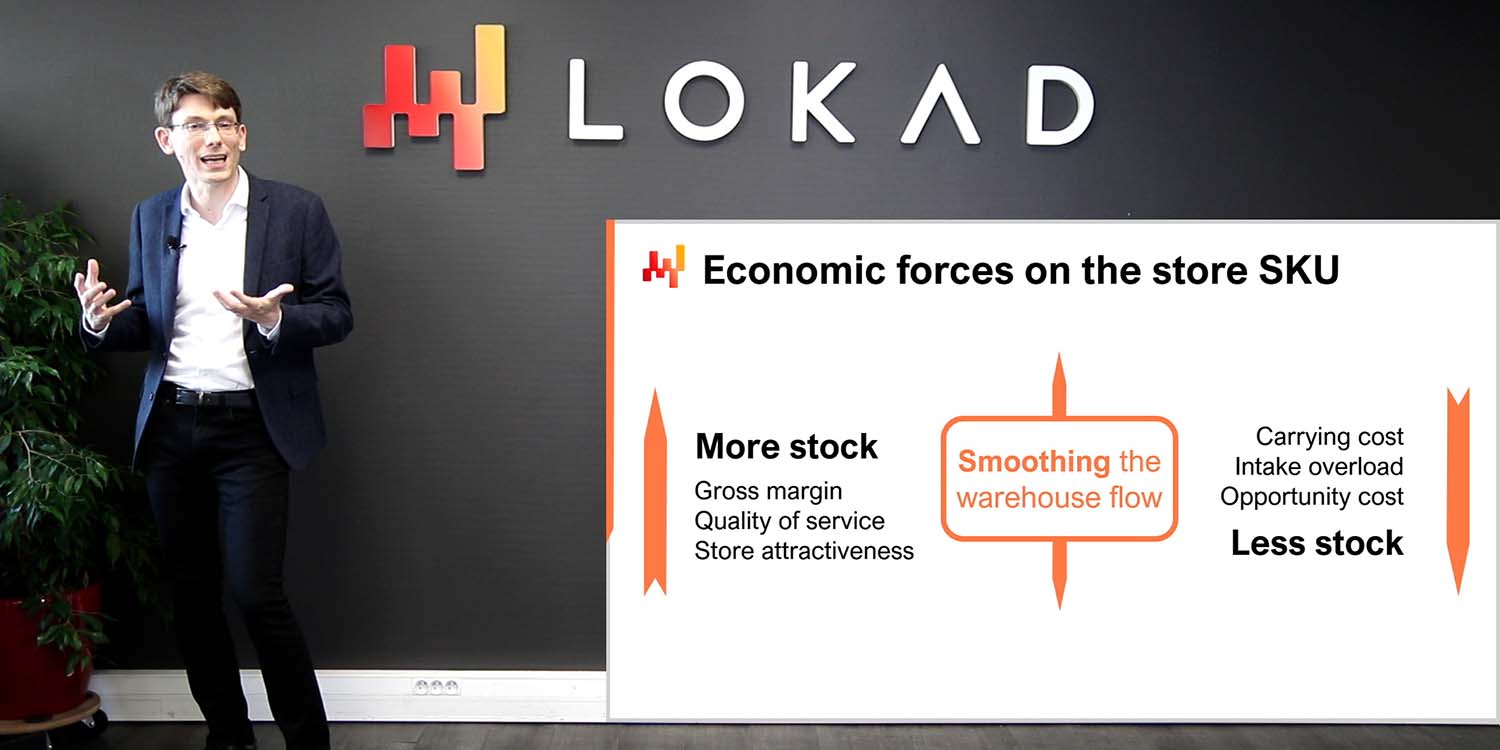

Retail stock allocation with probabilistic forecasts - Lecture 6.1

Supply chain decisions require risk-adjusted economic assessments. Converting probabilistic forecasts into economic assessments is nontrivial and require dedicated tooling. However, the resulting economic prioritization, illustrated by stock allocations, proves itself more powerful than traditional techniques. We start with the retail stock allocation challenge. In a 2-echelon network that includes both a distribution center (DC) and multiple stores, we need to decide how to allocate the stock of the DC to the stores, knowing that all stores compete for the same stock.

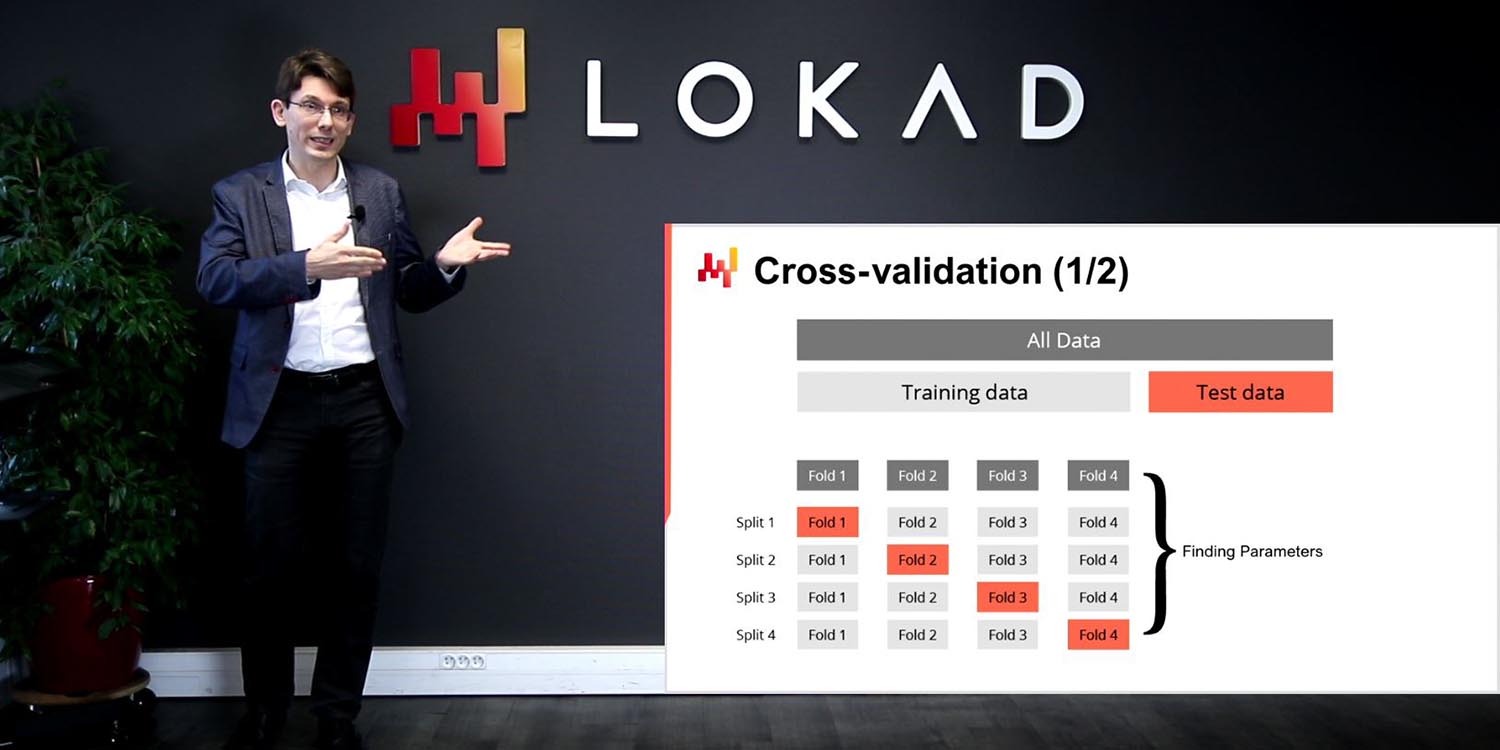

Probabilistic Forecasting for Supply Chain - Lecture 5.2

A forecast is said to be probabilistic, instead of deterministic, if it contains a set of probabilities associated with all possible future outcomes, instead of pinpointing one particular outcome as the forecast.

Structured predictive modeling for Supply Chain - Lecture 5.1

Differentiable Programming (DP) is a generative paradigm used to engineer a broad class of statistical models, which happen to be excellently suited for predictive supply chain challenges.