Supply Chain In 3 Minutes

BACK TO LOKAD TV ›

Why FIFO Fails - Supply Chain in 3 minutes

FIFO is simple, but often costly. Discover why it fails in complex repair scenarios—and how AI and financial optimization offer smarter alternatives.

Bill of Materials vs Bill of Resources - Supply Chain in 3 minutes

In a recent discussion, Conor Doherty highlights the critical differences between a bill of materials (BOM) and a bill of resources (BOR) for effective scheduling in manufacturing and repair operations. While a BOM lists the raw materials needed for production, a BOR includes not only these materials but also the necessary tools and skills. Doherty emphasizes that neglecting any component of the BOR can lead to production delays and increased costs. He argues that a comprehensive understanding of both BOM and BOR is essential for optimizing efficiency and minimizing financial risks in industrial processes.

Effects of AI on Supply Chain Jobs - Supply Chain in 3 minutes

Conor Doherty of Lokad scrutinizes a Harvard study on AI's impact on white-collar jobs, revealing nuanced effects. The research, involving 758 consultants, assesses AI's role in enhancing productivity, particularly in supply chain management. It finds that AI boosts performance in certain tasks, especially with training, but may falter in complex scenarios. Doherty critiques the study's narrow view of AI as an adjunct to human labor, arguing for its potential to fully automate tasks, thus revolutionizing productivity and redefining white-collar work. He warns of overconfidence in job security, as AI's full capabilities could dramatically alter the employment landscape.

Essential Skills for Modern Supply Chain - Supply Chain in 3 minutes

Conor Doherty, Head of Communication at Lokad, emphasizes the evolution of supply chain management, highlighting three critical skills for future practitioners':' technical writing, digital literacy, and financial awareness. Technical writing is crucial for documenting complex processes, ensuring knowledge is preserved and shared. Digital literacy, encompassing coding and data analytics, is vital for interpreting vast data streams and solving intricate supply chain challenges. Financial awareness enables practitioners to understand the economic impact of their decisions, ensuring fiscal responsibility. These skills are essential for navigating the complexities of modern supply chains and making informed, prudent decisions.

Forecast Value Added - Supply Chain in 3 minutes

Conor Doherty, Lokad's technical writer, discusses Forecast Value Added (FVA), a diagnostic tool for evaluating the value of each step in the forecasting process. FVA integrates insights from various departments to enhance forecasting precision. Doherty notes that FVA presumes that greater forecasting accuracy is always beneficial, which is not always the case. He suggests that the focus should be on reducing monetary error rather than pursuing greater accuracy. He concludes that FVA could be used as a competence test, but does not validate the routine use of non-specialists for forecasting input.

Backorders - Supply Chain in 3 minutes

Backorders are purchase orders made to the supplier for products that are already out of stock from a given location being served. Backordering is the process of selling inventory that the company doesn’t currently have on hand, and can therefore only take place when the demand is captured in a formal manner.

Inventory Control - Supply Chain in 3 minutes

Inventory control encompasses all the processes that support the supply, the storage, and the accessibility of items in order to ensure their availability while minimizing inventory costs. It can be split into two major areas. The management of inventory and the optimization of inventory. When managing the inventory, the goal is to sustain a high productivity for all inventory operations.

Demand Driven Material Requirements Planning (DDMRP) - Supply Chain in 3 minutes

Demand Driven Material Requirements Planning (DDMRP) is a quantitative method intended to optimize the supply chain performance of multi-echelon manufacturing businesses. This method delivers the quantities to be either bought or manufactured for any SKU of a BOM. A BOM (Bill of Materials) represents the assemblies, components and parts needed to manufacture an end-product. DDMRP seeks to determine, at any point of time, how much more raw materials should be sourced and whether more units of any SKU should be produced.

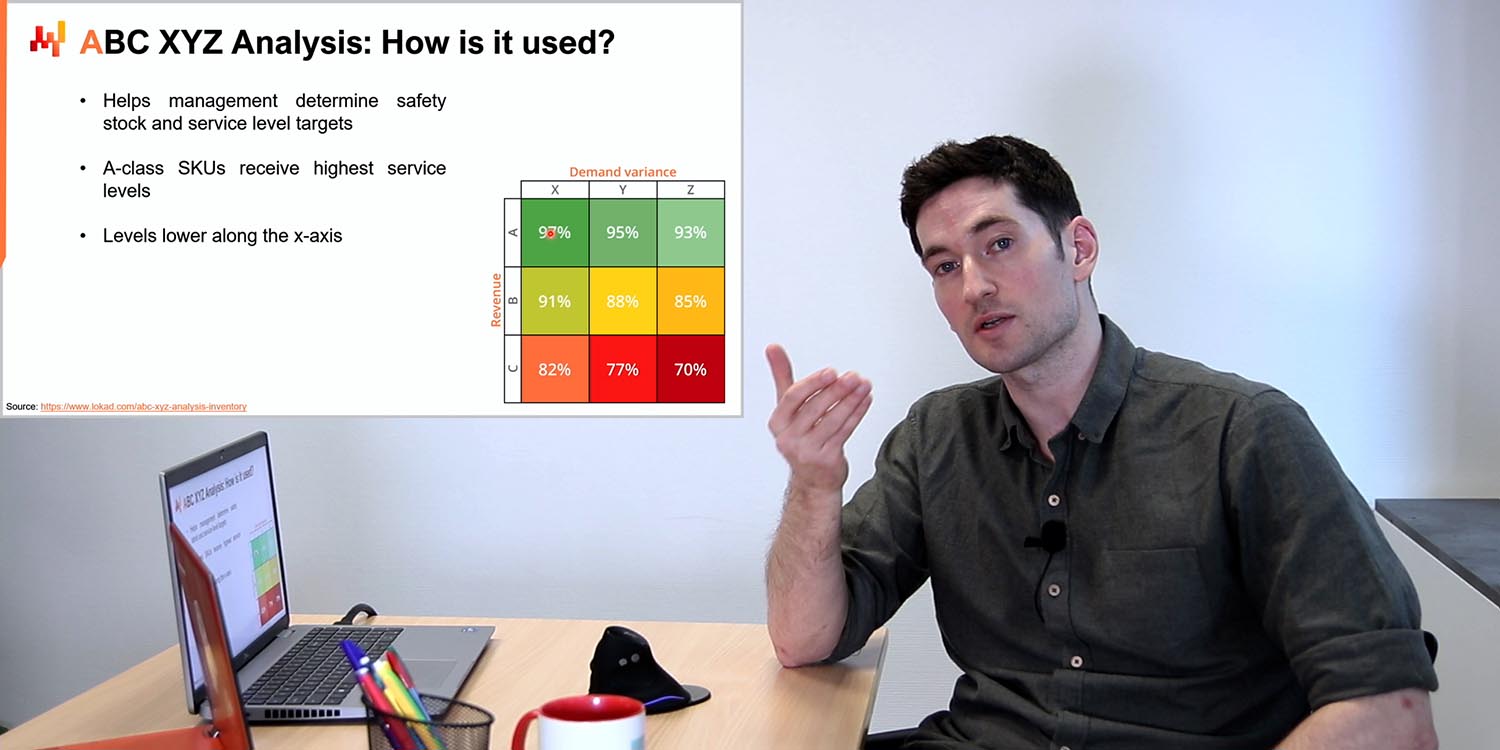

ABC XYZ - Supply Chain in 3 minutes

ABC XYZ Analysis is a categorization tool aimed at identifying the best-performing products in one’s catalog. This information is often used to set service level and safety stock targets. Unlike ABC Analysis, which focuses exclusively on a single variable (typically revenue), ABC XYZ attempts to quantify a second dimension (variance). In this tutorial, Conor explores ABC XYZ and delivers his verdict.

Debunking Supply Chain Terminology - Supply Chain in 3 minutes

In supply chains a sizable portion of supply chain terminology is inadequate. Good terminology should be as neutral and factual as possible, however this is far from the case in supply chain. We suggest changes to ABC analysis, service level, safety stock, seasonality, EOQ, BI and ERP, along with an explanation behind our proposed improvements.

Kanban - Supply Chain in 3 minutes

The Kanban method was initially implemented to improve manufacturing efficiency and reduce waste by providing a simple and visual material replenishment process so that every step of the production process would get just enough to operate smoothly without stockpiling raw materials or components.

Problem- vs Solution-oriented Software Design in 3 minutes

Every single SKU calls for mundane daily decisions, such as moving in more stock or changing the underlying price tag. Naturally, sticking to a fully manual process for those decisions is labor intensive and companies have been adopting varied software-based automation solutions.