All Episodes of Lokad TV

BACK TO LOKAD TV›

STS Component Solutions and Lokad: A Decade of Success (With Timothy Russo) - Ep 182

Conversation marking the 10-year Lokad–STS Component Solutions partnership, where Joannes Vermorel and Tim Russo discuss data-driven supply-chain innovation and future growth.

Defining Optimal Onsite Stock at Spairliners (with Elizabeth Peters)

Interview with Elizabeth Peters on Spairliners’ decade-long collaboration with Lokad, exploring parts-pooling challenges and the commercial edge it provides.

Why FIFO Fails - Supply Chain in 3 minutes

FIFO is simple, but often costly. Discover why it fails in complex repair scenarios—and how AI and financial optimization offer smarter alternatives.

Automating Supply Chain Decisions at Spairliners (with Remi Quentin)

Remi Quentin explains how Lokad's data-driven decision automation supports Spairliners' supply chain.

Why Supply Chain Digital Transformations Fail (Eric Kimberling) - Ep 181

Eric Kimberling and Joannes Vermorel discuss why supply chain digital transformations often fail, stressing the need for tech-agnostic strategies, change management, and alignment with business goals.

The State of Supply Chain Market Research - Ep 180

Conor Doherty and Joannes Vermorel expose vendor-biased market research and show how deep-search LLMs can deliver faster, fairer supply-chain insights.

Optimizing Aviation Pool Management at Spairliners (with Cyril Gaudard)

Tristan Oualid and Cyril Gaudard reflect on a 10-year Lokad–Spairliners partnership, highlighting how analytics, procurement, and collaboration drive smarter aviation pool management.

Analyzing Oil and Gas Supply Chain - Ep 179

In a reflective dialogue, Conor Doherty and Joannes Vermorel delve into supply chain challenges in the oil and gas industry, likening them to managing a miniature city rather than straightforward enterprises. Vermorel critiques conventional methods focused on criticality, advocating for automation and numerical models to enhance efficiency. He addresses the financial impact of long-tail events, emphasizing streamlined inventory practices over stockpiling. Vermorel highlights the inadequacy of systems like ERPs in decision-making, advocating for systems of intelligence to navigate future uncertainties. The conversation underscores the industry's conservative nature, where agility and digital optimization are crucial for advancing supply chain strategies.

What went wrong: SAP S4HANA - Ep 178

In an insightful discussion between Conor Doherty of Lokad and CEO Joannes Vermorel, they delve into the financial setbacks associated with SAP’s software implementations. Vermorel elucidates the fundamental problems of merging systems of records, systems of reports, and systems of intelligence into a single ERP solution, which leads to inefficiencies and conflicts. They highlight the costly failures experienced by companies like DHL and Lidl due to SAP’s flawed strategies, particularly the integration of HANA. Vermorel advocates for specialized systems and open-source solutions like PostgreSQL, which offer robust functionality at lower costs, steering companies away from complex, ineffective software amalgamations.

Conference with Joannes Vermorel at CentraleSupélec (French)

Joannes Vermorel, CEO and Founder of Lokad, delivered a lecture in French, sharing his journey in Supply Chain management. Vermorel recounted founding Lokad after graduating from École Normale Supérieure and shifting focus from bioinformatics to Supply Chain challenges. He discussed the development of Envision, Lokad's programming language, and the company's evolution since 2007. Vermorel criticized traditional Supply Chain theories, likening them to astrology, and emphasized the importance of challenging consensus. He highlighted Lokad's success with probabilistic methods and the impact of COVID-19 on Supply Chain robotization. Vermorel predicted the obsolescence of traditional roles and encouraged students to drive the industry's revolution.

Collaborative Supply Chain

In a recent LokadTV episode, Conor Doherty and Joannes Vermorel discuss the transformative potential of collaborative supply chains. Vermorel emphasizes that true collaboration transcends basic transactional relationships, requiring strategic synchronization and real-time data sharing across companies. He highlights the challenges posed by traditional IT systems and the reluctance to invest in long-term strategies. Lokad's innovative platform offers a solution by enabling secure, efficient data sharing, reducing friction and enhancing decision-making. Vermorel argues that while the concept isn't new, Lokad's approach makes it practical and affordable, encouraging companies to adopt collaborative practices for more resilient supply chains.

Mega AI Investments - Ep 176

In this episode of LokadTV, Conor Doherty and Joannes Vermorel discuss the recent AI investments announced by governments, including the Trump Administration's $500 billion and the European Union's 200 billion Euro commitments. Vermorel critiques these large-scale investments, arguing they are often inefficient and wasteful, with taxpayers bearing the costs. He emphasizes that successful innovations typically arise from focused, independent efforts rather than bureaucratic consortiums. Vermorel also questions the vague objectives of these investments and their impact on job creation, particularly in countries with regulatory issues. He advises focusing on specific, actionable innovations rather than state-led initiatives.

Bad Actors in Tech (with Anthony Miller) - Ep 175

Conor Doherty hosts a conversation with Anthony Miller (logistics consultant and writer) and Joannes Vermorel (founder of Lokad) about the prevalence of “bad actors” in enterprise technology—particularly within logistics and supply chain software. They discuss how bloated vendor promises, massive venture capital investments, and misleading analyst reports often lead to suboptimal or failed implementations. To avoid these pitfalls, they recommend examining a vendor’s actual product depth, financial stability, leadership consistency, and the clarity of the vendor’s communications—rather than relying on superficial rankings or buzzwords.

A Decade of Auditing Startups - Ep 174

In a recent LokadTV episode, Conor Doherty interviewed Joannes Vermorel, CEO of Lokad, about his decade-long experience conducting technical audits of startups. Vermorel's "lightning tech audits" offer venture capitalists expert evaluations of technological stacks, diverging from traditional methods by focusing on dynamic, context-specific assessments. His process involves intensive, one-day evaluations, including interviews with CTOs and engineering teams to gauge code quality and team functionality. Vermorel emphasizes the importance of passion, clear documentation, and wise resource use in tech development. His insights reveal significant industry oversights and highlight best practices for both investors and tech entrepreneurs.

10 Years of Success: Optimizing MRO Operations at Spairliners

In a recent interview, key figures from Spairliners and Lokad discussed their roles and collaborative efforts in the aviation industry. Rene Popp, Head of Engineering at Spairliners, emphasized efficient asset management and logistics. Quentin Roux, Supply Chain Team Leader, highlighted managing supplier relationships and repair orders. Remi Quentin from Lokad focused on optimizing supply chain processes through data science. Elizabeth Peters, Sales Director, discussed business development in North America. Cyril Gaudard, Team Leader Asset & Procurement, praised the dynamic industry and teamwork. The interview underscored the importance of collaboration, continuous learning, and strategic partnerships in overcoming aviation supply chain challenges.

No Such Thing as an Optimal Solution (with Ian Wright) - Ep 173

In a recent LokadTV interview, Conor Doherty hosted Ian Wright, founder of Logistics Sciences, and Joannes Vermorel, CEO of Lokad, to discuss the notion that there are no optimal decisions in supply chain management. They challenged traditional views on efficiency, highlighting the complexities and uncertainties that defy textbook ideals. Ian and Joannes emphasized that different stakeholders have varying definitions of optimality, and practical solutions must align with business realities. They discussed the limitations of traditional optimization methods and the importance of human judgment in strategic decision-making. The conversation underscored the need for models that handle uncertainty and focus on true economic outcomes.

Heuristics in Supply Chain - Ep 172

In a recent LokadTV episode, Conor Doherty, Communication Director at Lokad, interviewed Joannes Vermorel, CEO of Lokad, about heuristics in supply chain management. They discussed the use of simple problem-solving tools like FIFO and ABC analysis, highlighting their limitations and the need for more robust mathematical approaches. Joannes explained that while heuristics offer straightforward solutions, they often lack consistency and empirical validation. He emphasized the importance of distinguishing between true heuristics and arbitrary numerical recipes, advocating for real-world assessments and experiments to validate supply chain practices. The conversation underscored the necessity of critical evaluation and empirical evidence in optimizing supply chain decisions.

In Defense of S&OP (with Eric Wilson) - Ep 171

In a recent LokadTV interview, Conor Doherty hosted a discussion between Joannes Vermorel, CEO of Lokad, and Eric Wilson, Director of Thought Leadership at the Institute of Business Forecasting (IBF), focusing on Sales & Operations Planning (S&OP). Wilson, advocating for S&OP, highlighted its role in aligning company functions for coordinated decision-making and its benefits for mature companies. Vermorel critiqued S&OP as outdated, advocating for a software-centric approach to enhance efficiency and reduce human intervention. The debate covered the effectiveness of meetings, incremental versus radical changes, opportunity costs, and the future of S&OP, with both agreeing on the need for significant technological advancements.

Supply Chain Debate - Is Forecast Value Added (FVA) a best practice or time-waster (with Jeff Baker) - Ep 171

In a debate moderated by Conor Doherty, the topic "Is Forecast Value Added (FVA) a best practice or a time-waster?" was explored by Jeff Baker and Joannes Vermorel. Jeff Baker, with extensive experience in supply chain management, argued in favor of FVA, emphasizing its value when applied correctly and structured, highlighting the importance of addressing biases and leveraging expert inputs. Conversely, Joannes Vermorel, CEO of Lokad, contended that FVA can be inefficient, advocating instead for financial optimization of supply chain decisions with probabilistic forecasts. The debate underscored the contrasting views on FVA's role in supply chain management, providing insights into improving decision-making processes.

Bill of Materials vs Bill of Resources - Supply Chain in 3 minutes

In a recent discussion, Conor Doherty highlights the critical differences between a bill of materials (BOM) and a bill of resources (BOR) for effective scheduling in manufacturing and repair operations. While a BOM lists the raw materials needed for production, a BOR includes not only these materials but also the necessary tools and skills. Doherty emphasizes that neglecting any component of the BOR can lead to production delays and increased costs. He argues that a comprehensive understanding of both BOM and BOR is essential for optimizing efficiency and minimizing financial risks in industrial processes.

Optimizing Scheduling in Aerospace (with Simon Schalit) - Ep 170

In a recent interview, Conor Doherty, Director of Communication at Lokad, and Simon Schalit, COO, discussed Lokad's breakthrough in scheduling optimization for aerospace, particularly in aircraft manufacturing and MRO operations. They highlighted the complexity of coordinating numerous interdependent parts, skills, and equipment, which traditional methods struggle to manage. Lokad's approach shifts from a Bill of Materials (BOM) to a Bill of Resources (BOR), considering all necessary resources and their variability. Utilizing computational algorithms, Lokad can quickly generate practical solutions, minimizing financial risk and downtime. This integration of automation and human strategic insights is crucial for efficient and effective scheduling in complex environments.

What is a Supply Chain Scientist (with Simon Schalit) - Ep 169

In an interview, Conor Doherty of Lokad speaks with Simon Schalit, COO, about the crucial role of a Supply Chain Scientist at Lokad. Schalit explains that these scientists are not just data experts but also specialists in supply chain management, responsible for optimizing and automating decisions related to inventory and pricing. They build algorithms to ensure efficient purchasing and dispatch, aiming for maximum return on investment. Unlike typical data scientists, supply chain scientists immerse themselves in understanding business processes and strategies, translating them into optimization algorithms. This role involves data analysis, client interaction, and business acumen, making it essential for driving efficiency and profitability in businesses.

AI-Powered Supply Chain optimization at Tokic group

In a recent interview, Fabian Hoehner, Commercial Director at Lokad, and Elliot Langella, Lead Supply Chain Scientist at Lokad, discussed their participation in the ATR digital conference in Athens, hosted by the Tokic group, a Croatian automotive aftermarket company. They highlighted the integration of AI in the automotive aftermarket sector, focusing on their three-year collaboration with Tokic. This partnership, which began in late 2021, aimed to optimize stock levels and improve supply chain efficiency through AI-driven decision-making and demand forecasting. The results included a 5% increase in service levels and a 10% rise in sales, showcasing the transformative potential of AI in supply chain management.

Tokic's AI journey - Trial & errors, then efficient predictive Supply Chain with Lokad (with Josip Kelava)

Discover how Tokic, a leader in the Croatian automotive aftermarket, is transforming its operations with AI and data-driven strategies. In this exclusive interview from Athens, CTO Josip Kelava reveals how Tokic is leveraging Lokad expertise to tackle complex supply chain challenges and automate critical processes.

Why AI Initiatives Fail in Supply Chain - Ep 168

In a recent LokadTV episode, Conor Doherty and Joannes Vermorel discussed the inherent flaws in mainstream supply chain management, particularly the over-reliance on AI. Vermorel criticized longstanding practices like Requests for Proposals, time series forecasting, safety stock formulas, and service levels, arguing they are outdated and economically unsound. He emphasized that AI cannot rectify these deep-seated issues, as it is not yet at human-level intelligence. Vermorel suggested that practical, experience-based adjustments by practitioners often compensate for these flawed methods. The conversation concluded with a Q&A session, highlighting the challenge of removing entrenched processes in large companies.

Lokad at Supply Chain Event 2024

Recorded in November 2024 in Paris, Conor Doherty (Communications Director at Lokad) reports on Lokad's second appearance at Supply Chain Event. This yearly French-language event is a major gathering of solution-providers in the industry. This time, Lokad hosted a panel discussion with French retail giant Maisons du Monde to discuss the intricacies of their supply chain partnership.

Spairliners x Lokad x Total Aviation (at MRO Europe)

Recorded in October 2024 ahead of MRO Europe in Barcelona, Lokad, Spairliners, and Total Aviation hosted a rooftop networking event with many of the world's top aerospace companies and professionals. The event was also an opportunity to celebrate the 10-year anniversary of the Lokad-Spairliners partnership.

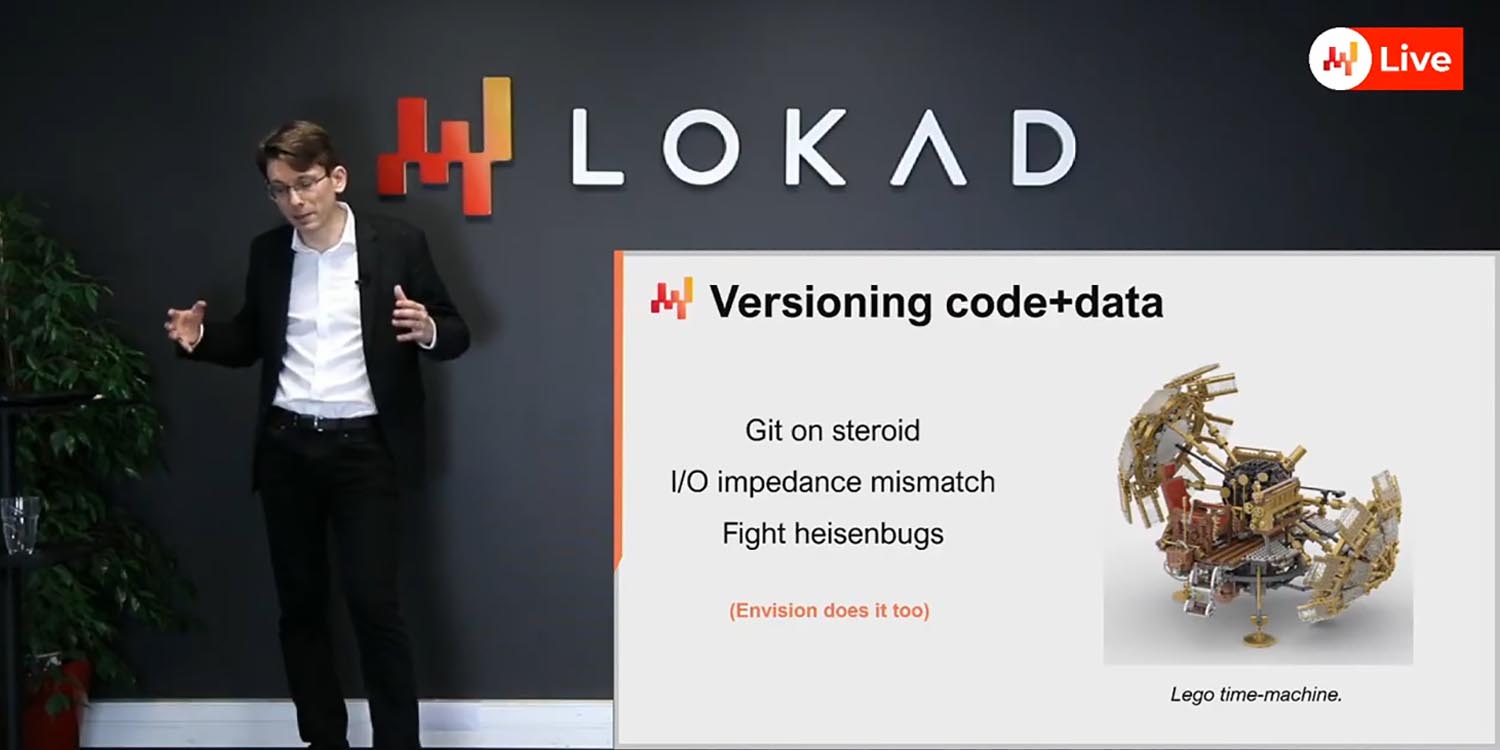

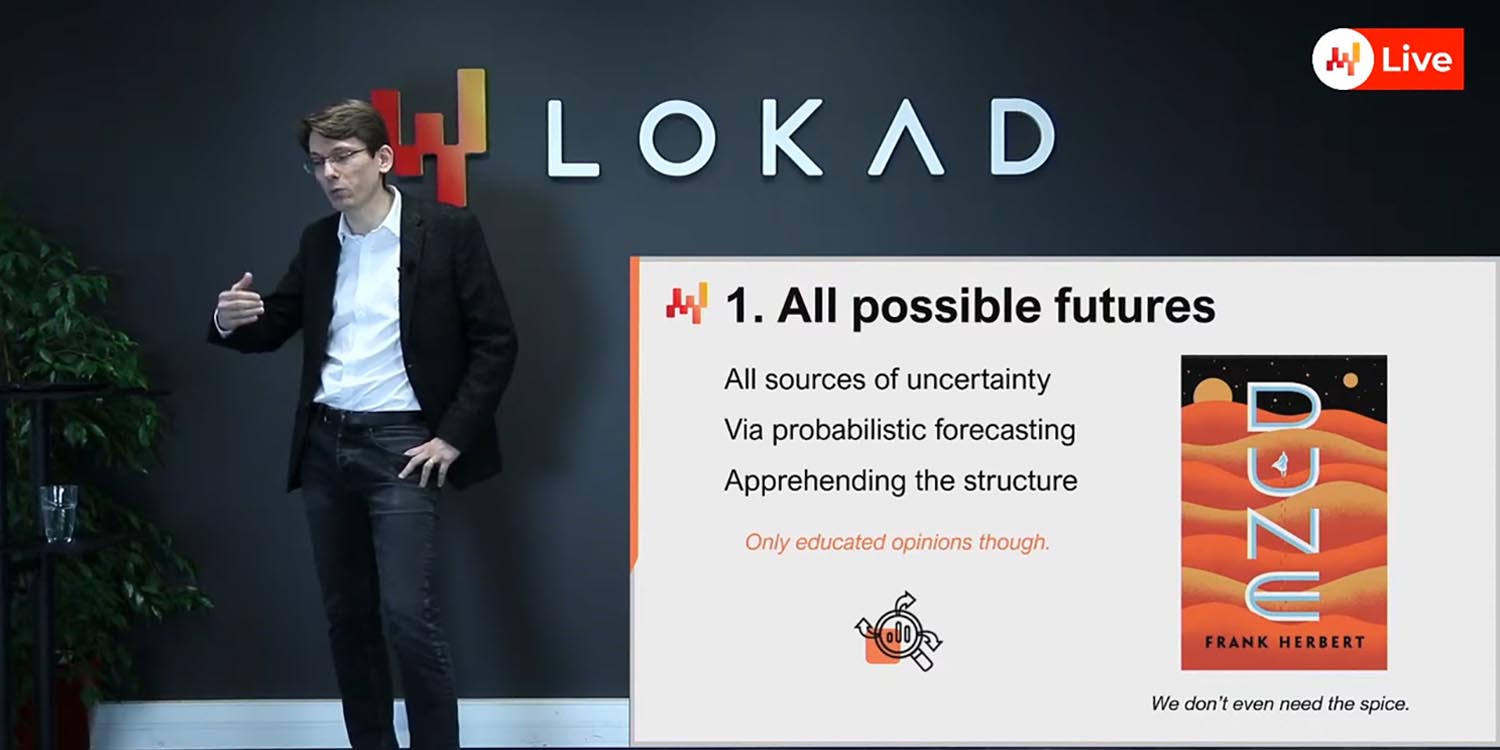

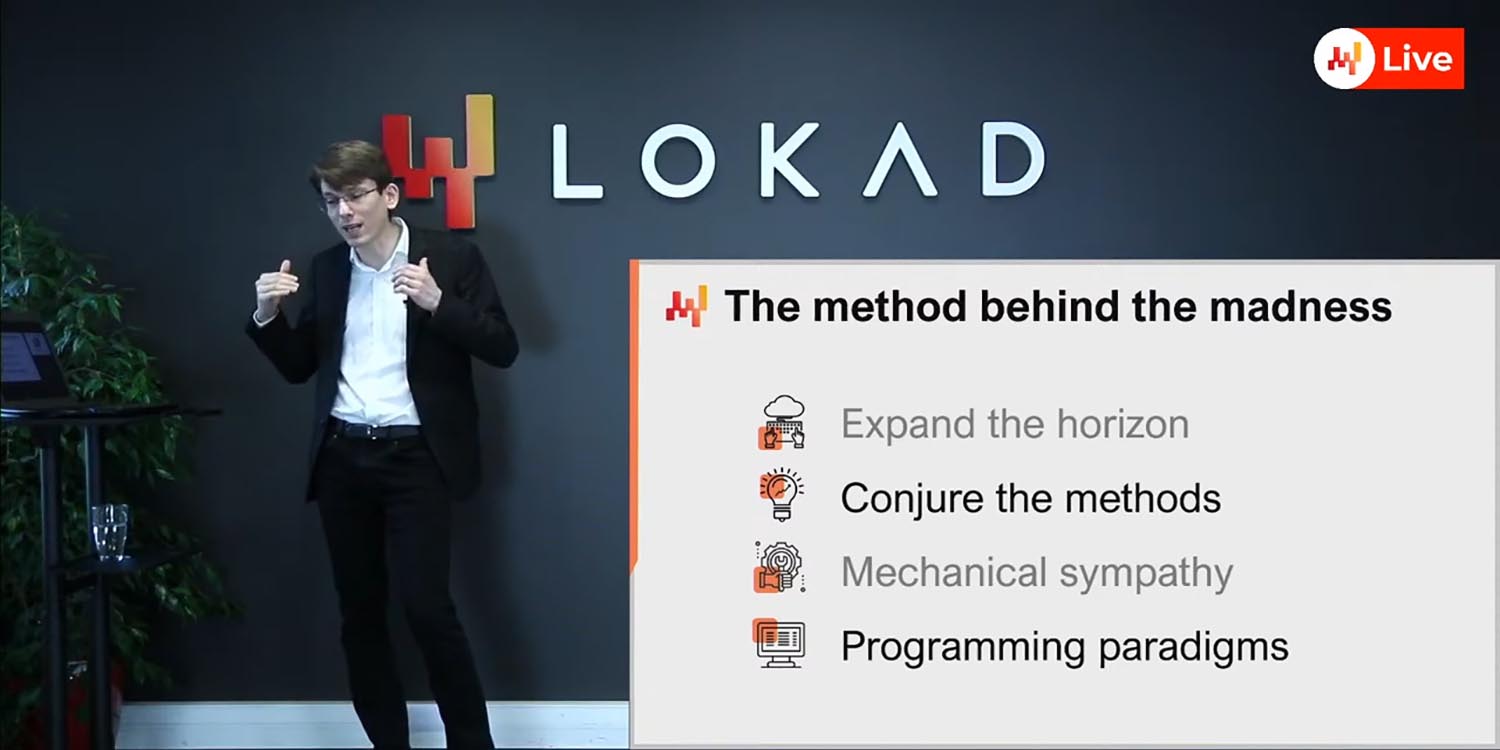

Computational Resources in Supply Chain - Ep 167

In a recent LokadTV episode, Conor Doherty, Head of Communication at Lokad, conversed with Joannes Vermorel, CEO of Lokad, about the critical role of computational resources in supply chain optimization. Vermorel emphasized the necessity of understanding both hardware and software to make informed supply chain decisions. He likened this foundational knowledge to basic geographical awareness, essential for preventing problems and ensuring effective decision-making. Vermorel highlighted that while computers are tools for mechanizing decisions, a grasp of their capabilities and limitations is crucial. This understanding extends to programming paradigms, ensuring practitioners can optimize resources and drive better outcomes.

Quantifying Uncertainty: A Roundtable at SCE2024 on Forecasting and Planning for the Modern Supply Chain

Moderated by Kevin Baumann, Lead Supply Chain Scientist at Lokad, this roundtable brought together senior executives from the retail sector for an in-depth discussion on the challenges and opportunities of the modern supply chain.

Supply Chain is not Logistics - Ep 166

Conor Doherty and Joannes Vermorel delve into the distinctions between supply chain and logistics, with supply chain a decision-making process and logistics a decision-execution one.

Supply Chain Debate On the Demand Driven Adaptive Enterprise Model (with Carol Ptak) - Ep 165

Carol Ptak (Demand Driven Institute) and Joannes Vermorel (Lokad) debate the Demand Driven Adaptive Enterprise Model.

Lokad: Artificial Intelligence in the Service of the Supply Chain

Lokad's Co-founder, Estelle Vermorel, was a guest on the Talk Entreprise show by Challenges.

ISF2024 Panel: Demand Planning & Human Judgement in the World of AI

At the 44th International Symposium on Forecasting, Lokad's Conor Doherty and Alexey Tikhonov joined a panel discussion on "Demand Planning and the Role of Judgment in the New World of AI/ML".

Optimizing Omnichannel Purchase & Allocation at Worten (with Bruno Saraiva)

In an onsite interview, Bruno Saraiva (Head of Stock & Space Management at Worten Portugal) discusses Worten's ongoing supply chain revolution.

Supply Chain Debate - Is S&OP a net good for companies? (with Milos Vrzic) - Ep 164

In a debate hosted by Conor Doherty of Lokad, Milos Vrzic, former Head of Supply Chain at Galderma, and Joannes Vermorel, CEO of Lokad, discussed the value of S&OP for companies. Vermorel critiqued S&OP as simplistic and outdated, while Vrzic emphasized its role in tactical planning. The debate highlighted the complexities of S&OP and the need for a nuanced understanding of its role in business.

Probabilistic Forecasts & Sequential Decision-Making (with Warren Powell) - Ep 163

In a recent LokadTV interview, Conor Doherty, Joannes Vermorel, and guest Warren Powell discussed probabilistic forecasts and decision making in supply chains. Warren Powell, a retired Princeton professor and Chief Innovation Officer at Optimal Dynamics, shared his career journey and insights on planning under uncertainty. Joannes Vermorel, Lokad's CEO, discussed his transition from deterministic methods to probabilistic forecasting, criticizing academia's lack of real-world application. Both agreed on the superiority of probabilistic forecasting, despite its complexity and businesses' struggle to apply it. The conversation highlighted the need for a broader perspective and a unified approach to dealing with uncertainty in decision-making.

Decision-making under Uncertainty in Supply Chain (with Dr. Meinolf Sellmann) - Ep 162

In a recent LokadTV interview, Conor Doherty, Joannes Vermorel, and guest Meinolf Sellmann discussed the role of stochastic optimization in supply chain management. They highlighted the importance of considering variability and uncertainty in decision-making processes. Traditional deterministic methods often fall short in real-world scenarios, leading to over-optimistic optimization plans. Both Vermorel and Sellmann criticized the "predict then optimize" approach, suggesting that companies can achieve better results by accounting for forecast variability during optimization. They emphasized the need for executable plans and measurable effectiveness in any optimization model.

Forecast Congruence and Supply Chain Decision-Making (with Nikolaos Kourentzes) - Ep 161

In a recent LokadTV interview, Nikos Kourentzes, a professor at the University of Skövde, and Joannes Vermorel, CEO of Lokad, discussed forecast congruence in supply chain decision-making. They emphasized the importance of aligning forecasts with decisions, acknowledging that models may be misspecified. They distinguished between forecasting accuracy and congruence, arguing that the most accurate forecast may not be the best for decision-making if it doesn't align with the decision's objective. They also discussed the practical application of forecasting congruence in inventory decision making and its potential to mitigate the bullwhip effect. The role of AI and human involvement in forecasting congruence was also discussed.

Quality-Cost Dilemma in Supply Chain - Ep 160

In a dialogue with Lokad's Head of Communication, Conor Doherty, Lokad CEO Joannes Vermorel discusses the quality-cost ratio in supply chain management. Vermorel emphasizes that quality refers to decision-making, not product attributes, and that client-perceived quality may not align with optimal supply decisions due to cost. He criticizes traditional KPIs, arguing they don't reflect genuine quality. Vermorel also discusses the role of Large Language Models (LLMs) in supply chain management, noting they can lead to smarter decisions but can inflate IT budgets. He suggests the quality-cost dilemma is a meta game, requiring software engineering to solve supply chain problems and assess trade-offs.

AI Pilots in Supply Chain - Ep 159

In a dialogue between Lokad's CEO Joannes Vermorel and Head of Communication Conor Doherty, they discuss the impact of AI on supply chain management. Vermorel highlights the advancements in AI and large language models, which have revolutionized task automation. He introduces AI Pilots, a Lokad offering that automates decision-making and clerical tasks, facilitated by Lokad's proprietary programming language, Envision. Vermorel also discusses the potential of AI to automate tasks related to Master data and contrasts Lokad's approach with competitors. He predicts that AI Pilots will become the norm in supply chain management, leading to significant productivity improvements. The conversation concludes with a Q&A session.

Effects of AI on Supply Chain Jobs - Supply Chain in 3 minutes

Conor Doherty of Lokad scrutinizes a Harvard study on AI's impact on white-collar jobs, revealing nuanced effects. The research, involving 758 consultants, assesses AI's role in enhancing productivity, particularly in supply chain management. It finds that AI boosts performance in certain tasks, especially with training, but may falter in complex scenarios. Doherty critiques the study's narrow view of AI as an adjunct to human labor, arguing for its potential to fully automate tasks, thus revolutionizing productivity and redefining white-collar work. He warns of overconfidence in job security, as AI's full capabilities could dramatically alter the employment landscape.

Rethinking S&OP (The Future of Supply Chain) - Ep 158

Lokad CEO Joannes Vermorel critiques the Sales and Operation Planning (S&OP) process as outdated and inefficient for modern businesses. He argues that S&OP, designed for simpler times, struggles to keep pace with today's complex, fast-moving business environment. Vermorel criticizes the process' slow refresh rate, its reliance on meetings and spreadsheets, and its focus on unified forecasts. He suggests that large companies should eliminate their S&OP divisions, likening them to obsolete fax machines. Instead, he proposes a shift towards improving access to information, transforming S&OP teams into data lake teams.

Stocks are not in your control - Ep 157

In this LokadTV eposide, Conor Doherty interviewed Joannes Vermorel on inventory planning misconceptions. Vermorel dismantled the fallacy that stock levels are a direct lever for client satisfaction and profitability. He argued that companies should focus on serving clients profitably, not on the illusion of stock control. Vermorel criticized simplistic inventory policies like min-max, stressing that stock levels are influenced by myriad factors beyond direct control. He advocated for prioritizing quality supply chain decisions over stock level targets, which often fail to account for dynamic business realities. The conversation highlighted the need for a nuanced approach to supply chain management, emphasizing decision control over uncontrollable outcomes.

Essential Skills for Modern Supply Chain - Supply Chain in 3 minutes

Conor Doherty, Head of Communication at Lokad, emphasizes the evolution of supply chain management, highlighting three critical skills for future practitioners':' technical writing, digital literacy, and financial awareness. Technical writing is crucial for documenting complex processes, ensuring knowledge is preserved and shared. Digital literacy, encompassing coding and data analytics, is vital for interpreting vast data streams and solving intricate supply chain challenges. Financial awareness enables practitioners to understand the economic impact of their decisions, ensuring fiscal responsibility. These skills are essential for navigating the complexities of modern supply chains and making informed, prudent decisions.

Stochastic Optimization of Supply Chain Decisions - Ep 156

In a discussion between Lokad's CEO, Joannes Vermorel, and Head of Communication, Conor Doherty, the importance of stochastic optimization and probabilistic forecasting in supply chain management is emphasized. Vermorel explains the concept of stochasticity, where the loss function is uncertain, a common occurrence in supply chain scenarios. He outlines the three ingredients of mathematical optimization':' variables, constraints, and the loss function, and explains that in stochastic optimization, the loss function is not deterministic but randomized. Vermorel also discusses the scalability issues of mathematical optimization techniques for supply chain, which have been a roadblock for four decades. He concludes by emphasizing that stochastic optimization is a crucial aspect often overlooked in supply chain textbooks.

A day to day exhibition of Lokad usage in a MRO company (with Rodrigo Pineda)

In a conversation revealing the intricacies of aviation MRO supply chain management, Baptiste Miceli of Lokad and Rodrigo Pineda of MRO Holdings discussed the challenges of standardizing inventory planning across diverse operations. Pineda detailed efforts to harmonize procurement strategies and risk management for MRO Holdings, emphasizing the need for profitability in their standalone operations. Lokad's tailored software solutions aided in creating a unified material planning process, despite the volatility of demand in the MRO industry. Their event-based forecasting provided a clearer prediction model, leading to satisfaction and a commitment to ongoing improvement in managing the ever-changing supply chain landscape.

Traditional Jobs vs AI in Supply Chain - Ep 155

In a conversation between Conor Doherty and Joannes Vermorel of Lokad, Vermorel predicts that Artificial Intelligence (AI) will lead to a mass extinction of back office white-collar jobs by 2030, much sooner than previous predictions. He attributes this to the success of Large Language Models (LLMs), which he believes will impact all back office jobs, particularly in supply chains. Vermorel argues that the goal should be complete automation for repetitive jobs, unlocking significant productivity improvements. He predicts that many companies will start removing people from these positions within months. Vermorel suggests that tasks requiring high-level human intelligence, such as strategic decisions, are still beyond the capabilities of LLMs.

RFP Madness - Ep 154

Joannes Vermorel challenges the conventional wisdom of procurement processes, questioning the necessity of RFIs, RFPs, and RFQs. He argues these documents are more habitual than essential, suggesting that procurement involves both indispensable and arbitrary steps.

Resilience, Risk, and Effective Leadership (with Knut Alicke) - Ep 153

Knut Alicke of McKinsey joins Lokad to discuss the need for systematic planning and digital tool utilization, as well as his recent (co-authored) book, From Source to Sold. Alicke emphasizes the importance of visibility and pre-warning systems to detect potential disruptions, and elucidates some of the key ingredients for successful supply chain leadership.

The future of supply chain practice - Discussion with Joannes Vermorel at the Ecole des Mines de Paris (French)

Recorded at Paris' Ecole des Mines in summer 2023, Lokad CEO and founder, Joannes Vermorel, explains the quantitative supply chain perspective in detail and how it will shape the future of supply chain practice.

Large Language Models in Supply Chain (with Rinat Abdullin)

In a recent dialogue, Conor Doherty of Lokad conversed with Joannes Vermorel and Rinat Abdullin about generative AI's impact on supply chains. Vermorel, Lokad's CEO, and Abdullin, a technical consultant,discussed the evolution from time series forecasting to leveraging Large Language Models (LLMs) like ChatGPT. They explored LLMs' potential to automate tasks, enhance productivity, and assist in data analysis without displacing jobs. While Vermorel remained cautious about LLMs in planning, both acknowledged their utility in composing solutions. The interview underscored the transformative role of AI in supply chain management and the importance of integrating LLMs with specialized tools.

The Role of Scarcity in Supply Chain

In a dialogue with Conor Doherty, Joannes Vermorel, founder of Lokad, criticizes mainstream supply chain theory for overlooking resource scarcity and alternative uses. Joannes Vermorel argues that traditional theory assumes a known future, eliminating the need for resource allocation decisions. He emphasizes the importance of time in supply chain management, stating that no resource is truly scarce given enough time. Joannes Vermorel also criticizes the mainstream view for ignoring the complexities of allocation decisions and the importance of financial assessments. He suggests that supply chain optimization should involve probabilistic forecasting and stochastic optimization, assessing all possible futures and making decisions based on expected returns.

MRO Holdings' Quantitative Supply Chain Revolution (with Ricardo Alvarez Henao)

In a recent dialogue, Ricardo Alvarez Henao, Supply Chain Director at MRO Holdings, shared insights on the aviation MRO sector with Luciano Lisiotti of Lokad. Alvarez Henao emphasized the importance of anticipation and visibility in supply chain risk management, noting that inaccurate forecasts could lead to operational delays or surplus inventory. He also highlighted emerging trends in the MRO industry, including a post-pandemic bounce back, a trend towards partnerships, and the increasing complexity of demand. Alvarez Henao stressed the importance of embracing volatility and complexity, and the usefulness of probabilistic demand planning and forecasting. He concluded that while the MRO sector is more complex than the fast-moving consumer goods sector, the principles of leading a supply chain are similar.

Quantitative Supply Chain: What our clients think

Lokad is fortunate to collaborate with many significant clients across a diverse range of verticals. The challenges each client faces are unique and thus require tailored, programmatic, and automated solutions. Hear what some of our clients have to say about their quantitative supply chain solutions!

The Evolution of Supply Chain Education (with Paul Jan)

Conor Doherty, host of Lokad TV, recently engaged in a discussion with Joannes Vermorel, founder of Lokad, and Paul Jan, a supply chain professor at the University of Toronto. The conversation centered on the evolving field of supply chain management, the role of data, and the importance of education. Vermorel introduced the concept of "wicked problems" in supply chain, highlighting the limitations of Excel and the need for tools like SQL Server. Jan shared his experience transitioning from Excel to more programmatic options, praising Lokad's tool, Envision. Both emphasized the need for industry disruption and the importance of education in supply chain management.

Risks in Supply Chain Management

Conor Doherty, LokadTV host, and Joannes Vermorel, founder of Lokad, discuss the inherent risks in supply chain management. Vermorel emphasizes that the primary risk is the uncertainty of the future, which is irreducible and beyond control. He notes that every decision involves a trade-off between risk and reward, and that zero risk is unattainable. Vermorel also highlights the opportunities that can arise from these risks, such as capitalizing on market shortages. He advocates an agile and opportunistic mindset, and the use of probabilistic forecasting to mitigate risk. Vermorel and Doherty conclude by agreeing that even small companies can benefit from risk management, leading to increased margins and cash flow.

Supply Chain Board Games (with Mathias Le Scaon)

In a LokadTV interview, Lokad's Conor Doherty converses with Joannes Vermorel of Lokad and Mathias Le Scaon of Zensimu about the development and purpose of supply chain games. Zensimu creates online games to educate on supply chain topics, while Lokad has released a board game, SkuZ, to make supply chain practice more engaging. Both founders discuss the challenges of balancing realism, learning, and entertainment in game design. They also touch on the potential of AI in supply chain games, with Mathias expressing skepticism due to added complexity. Both commit to continuous improvement and innovation in their games.

Forecast Value Added - Supply Chain in 3 minutes

Conor Doherty, Lokad's technical writer, discusses Forecast Value Added (FVA), a diagnostic tool for evaluating the value of each step in the forecasting process. FVA integrates insights from various departments to enhance forecasting precision. Doherty notes that FVA presumes that greater forecasting accuracy is always beneficial, which is not always the case. He suggests that the focus should be on reducing monetary error rather than pursuing greater accuracy. He concludes that FVA could be used as a competence test, but does not validate the routine use of non-specialists for forecasting input.

Customizing Trek Bikes (Mastering Configurability with Dan Scharneck) - Ep 147

In a dialogue moderated by Conor Doherty, Joannes Vermorel of Lokad and Dan Scharneck, the Director of Supply Chain at Trek Bicycle explored the intricacies of supply chain management for customizable products. Vermorel emphasized the combinatorial complexity of supply chains, noting that companies are using them as a differentiator for customer experience. Scharneck agreed, highlighting the importance of delivering custom products promptly and reliably. He acknowledged the challenges of managing inventory with traditional ERP systems, leading Trek to adopt Lokad's more adaptable solution. Vermorel explained that Lokad uses probabilistic forecasts to assess the risk of bottlenecks, providing a more powerful perspective on supply chain delays. Both agreed on the importance of managing supply chain complexity and the value configurability offers to customers.

Does forecast accuracy even matter?

Joannes Vermorel, CEO of Lokad, criticizes the traditional understanding of forecast accuracy in supply chain management, arguing that it doesn't reflect the core DNA of a business. He suggests that time series forecasts, which are commonly used, are overly simplistic and do not accurately represent the future for supply chain purposes. Vermorel proposes a different approach, focusing on being quantitatively faithful to the essence of a company. He criticizes the focus on incremental improvements and suggests that companies should look for simpler, better solutions. Vermorel emphasizes the importance of understanding the essence of the problem and producing quantifiable statements that make sense for the business.

Innovating Inventory management at Celio with Julie Schaf

In this interview recorded in spring 2023 at a Celio store in Rosny-sous-Bois, Joannes Vermorel (founder of Lokad) and Julie Schaf (Supply Chain Director at Celio), discuss their ongoing supply chain optimization partnership. Schaf praises Lokad's approach, which differs from traditional tools by focusing on product value, optimizing shortage management, and offering high responsiveness to evolving needs. She points out that Lokad anticipates shortages and prioritizes the dispatch of high-performing products to the most profitable stores for each given item. Their close collaboration facilitates rapid adaptation to required changes, generating beneficial economic and operational impacts for Celio.

MRO Complexity Explained (Paris Air Show 2023)

Effective MRO (maintenance, repair and overhaul) requires meticulous management of up to several million parts per plane, where any unavailability can result in costly aircraft-on-ground (AOG) events. Traditional solutions to manage this complexity involve implementing safety stock formulas or maintaining excessive inventory, both of which have limitations and can be financially untenable. Lokad, through a probabilistic forecasting approach, focuses on forecasting the failure or repair needs of every individual part across the fleet and assessing the immediate and downstream financial impact of potential AOG events.

Backorders - Supply Chain in 3 minutes

Backorders are purchase orders made to the supplier for products that are already out of stock from a given location being served. Backordering is the process of selling inventory that the company doesn’t currently have on hand, and can therefore only take place when the demand is captured in a formal manner.

Inventory Control - Supply Chain in 3 minutes

Inventory control encompasses all the processes that support the supply, the storage, and the accessibility of items in order to ensure their availability while minimizing inventory costs. It can be split into two major areas. The management of inventory and the optimization of inventory. When managing the inventory, the goal is to sustain a high productivity for all inventory operations.

Spilling to Disk in .NET

In order to process more data than can fit in memory, programs can spill some of that data to a slower but larger storage, such as NVMe drives. Through a combination of two rather obscure .NET features (memory-mapped files and memory managers), this can be done from C# with little to no performance overhead. This talk given at Warsaw IT Days 2023 dives into the deep details how this works, and discusses how the open source NuGet package Lokad.ScratchSpace hides most of those details from developers.

Stock Optimization at Air France Industries with Stephan Lise

Recorded in the autumn of 2022 at Air France's aircraft engine repair facilities, the interview features Stéphan Lise and Joannes Vermorel discussing "Prognos for Inventory", a collaborative tool between Lokad and Air France for optimized stock management in the aerospace industry. They emphasize the complexity of the sector, especially the prediction of needs for expensive parts. The tool proved crucial during the COVID-19 crisis, quickly adapting operations. Mr. Lise highlights the agility of Prognos for Inventory compared to other enterprise solutions, emphasizing its ability to adapt to user processes while allowing effective inter-process communication.

Demand Driven Material Requirements Planning (DDMRP) - Supply Chain in 3 minutes

Demand Driven Material Requirements Planning (DDMRP) is a quantitative method intended to optimize the supply chain performance of multi-echelon manufacturing businesses. This method delivers the quantities to be either bought or manufactured for any SKU of a BOM. A BOM (Bill of Materials) represents the assemblies, components and parts needed to manufacture an end-product. DDMRP seeks to determine, at any point of time, how much more raw materials should be sourced and whether more units of any SKU should be produced.

Managing a fashion supply chain at Celio With David Teboul

In this interview recorded onsite at a Celio store in Rosny-sous-Bois, Joannes Vermorel and David Teboul (Managing Director of Operations at Celio) discuss the resurgence of Celio following the challenges of 2020-2021. David highlights the importance of a "normal" customer-focused approach in transforming the brand. Lokad supported this transformation by assisting in optimizing the supply chain to better cater to a diverse range of stores and offers. Despite increasing complexity and the rise of online commerce, David emphasizes the need for agility and the critical role of physical stores for Celio, while striving to understand and meet customer needs through various touchpoints.

On Knowledge, Time and Work for Supply Chains - Lecture 1.7

Supply chains abide by the general economic principles. Yet, these principles are too little known and too frequently misrepresented. Popular supply chain practices and their theories often contradict what is generally agreed upon in economics.

The Supply Chain of the Future at Air France Industries with Guillaume Adrien

Guillaume Adrien, VP of Supply Chain Design and Performance at Air France Industries, and Joannes Vermorel, Lokad's founder, discuss the complexities of aviation supply chain optimization. Adrien explains that the nature of the industry demands swift response to unpredictable circumstances, with safety being a top priority. The collaboration with Lokad and the use of predictive optimization technology has resulted in noticeable improvements in non-stock management and other supply chain areas. Emphasizing the ongoing transformation of Air France's supply chain, Adrien highlights the need for adaptability, curiosity, data-driven mindsets, and innovation in aspiring engineers. The goal is to create a digital twin of the supply chain for potential optimizations.

Virtue Signaling in Supply Chain - Ep 145

In a comprehensive discussion spanning philosophy, law, ethics, and economics, Conor Doherty and Joannes Vermorel, Lokad founder, dissect the role of virtue within corporations and supply chains. Vermorel articulates the necessity for corporate values that benefit not only the company but also its employees and society at large, for long-term profitability. He highlights the importance of legal frameworks to balance profit-seeking and societal good. Vermorel explores challenges in long-term growth strategies, talent retention, and the intersection of internal and external values, especially for multinational corporations. He critiques virtue signaling as often disingenuous and unnecessary. Ultimately, Doherty is somewhat skeptical about the space for virtue in business, yet Vermorel is more sanguine and posits that corporations can't merely pretend to uphold virtues but must genuinely live up to them.

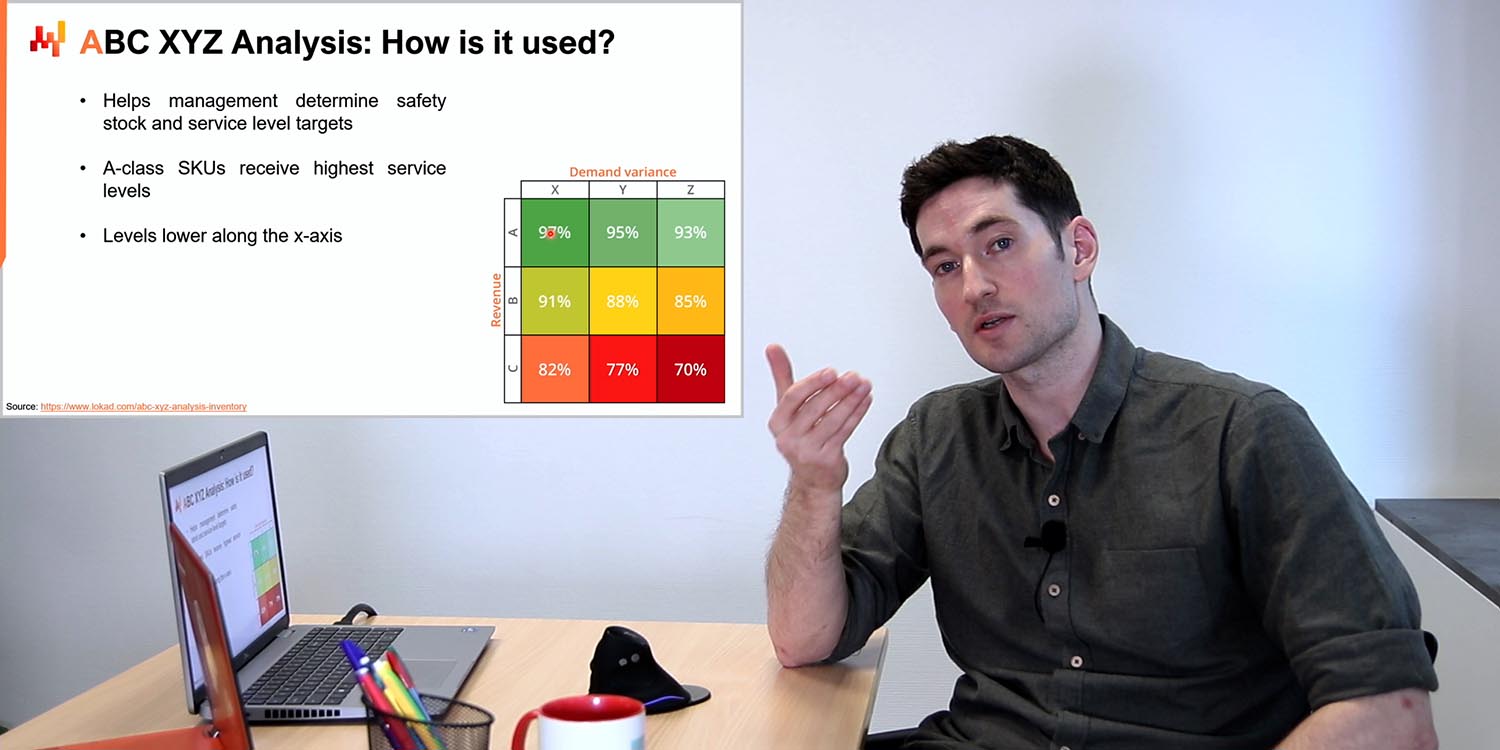

Analyzing ABC XYZ - Ep 144

Conor Doherty and Joannes Vermorel investigate popular stock analysis tool ABC XYZ Analysis, arguing its oversimplification leads to information loss. Vermorel challenges conventional practices of managing service levels and safety stock separately. Vermorel advocates for technology-aided supply chain management, given the complexity of handling large quantities of products. He criticizes the ABC XYZ analysis for lacking dynamism and not considering customers' perspectives. Vermorel favors a probabilistic approach to supply chain management, which can offer a more nuanced understanding of risks and aid in inventory decision-making.

The End of Certainty (White-boxing Probabilistic Forecasting with Pierre Pinson) - Ep 143

In an interview with Conor Doherty, Joannes Vermorel, founder of Lokad, and Pierre Pinson, Chair of Data-centric Design Engineering at Imperial College London, discuss probabilistic forecasting and its applications in various fields. They emphasize the importance of understanding uncertainty in forecasting and the need for ongoing education in the area. All three agree that innovation happens faster than people can embrace it, and they encourage staying updated on new developments in the field and being prepared for the advancements yet to come.

Pricing Optimization for the Automotive Aftermarket - Lecture 6.2

The balance of supply and demand very much depends on prices. Thus, pricing optimization belongs to the realm of supply chain, at least to a sizeable extent. We will present a series of techniques to optimize the prices of a fictitious automotive aftermarket company. Through this example, we will see the danger associated with abstract lines of reasoning that fail to see the proper context. Knowing what ought to be optimized is more important than the fine print of the optimization itself.

Aircraft Engine Maintenance Repair and Overhaul at Air France Industries with Fanny Kientz

Joannès meets Fanny Kientz -the Vice-President of Engine Supply Chain and Assets at Air France Industries (AFI)- to discuss about the path of the maintenance/repair process and all the associated constraints. The challenges for aircraft supply chain are also talked through, with a focus on the balance between costs and operational efficiency or post-pandemic adaptation. Fanny highlights the important contribution of Lokad to release the potential from the data, allowing AFI to optimize the entire activity.

Spare Part Optimization for Aircrafts at Air France Industries with Olivier Pelloux-Prayer

Aircraft components fail frequently and the costs of maintaining regular safety stock is prohibitive. What is the key to achieving the right balance between uninterrupted customer operations and having the right stock, at the right place at the right price? VP Assets and Outsourced Repairs of component division, Olivier Pelloux-Prayer, shares some advice on how to keep inventory at the best level while keeping customers satisfied.

Quantum Computing and Enterprise Software (with Olivier Ezratty) - Ep 142

Quantum technology expert Olivier Ezratty discusses with Joannes Vermorel the potential of quantum computing, communication, and sensing. Quantum computing aims to harness quantum phenomena like superposition and entanglement to perform tasks beyond classical computers' capabilities. Quantum communication has applications beyond security, such as the quantum internet and distributed quantum computing. Quantum sensing can measure physical properties with unprecedented precision. Despite progress in the field, there is still a significant gap between theoretical knowledge and practical implementation. The timeline for widespread adoption remains uncertain, with experts estimating 10-15 years before quantum technology reaches its full potential.

ABC XYZ - Supply Chain in 3 minutes

ABC XYZ Analysis is a categorization tool aimed at identifying the best-performing products in one’s catalog. This information is often used to set service level and safety stock targets. Unlike ABC Analysis, which focuses exclusively on a single variable (typically revenue), ABC XYZ attempts to quantify a second dimension (variance). In this tutorial, Conor explores ABC XYZ and delivers his verdict.

Optimizing Retail Stock Allocation at Worten (with Bruno Saraiva) - Ep 141

Bruno Saraiva, Head of Stock and Space Management at Worten, joins Joannes and Conor in studio to discuss the challenges of retail stock allocation and Worten's collaboration with Lokad. Bruno also shares his experience in the retail industry and the crucial role of supply chain management in customer satisfaction. Saraiva shares his experience working with Lokad, noting that the company's approach has helped Worten make better inventory management decisions while still allowing employees the freedom to challenge and question recommendations. He believes that trust and collaboration between teams are crucial for a successful supply chain management strategy.

Piloting promotions with the help of Lokad at La Redoute

Exclusive interviews with Mary Leitao and Ludovic Bidault, Heads of Purchase Management at La Redoute, who graciously took the time to discuss La Redoute’s predictive optimization partnership with Lokad. La Redoute, the second largest women’s clothing retailer, chose Lokad to drive transformation around predictive optimization. The goal of this collaboration was to use artificial intelligence to better manage the match between pricing, sales performance, and inventory.

Generative AI in Supply Chain (ChatGPT and the Perils of Flimflam) - Ep 140

Generative AI – ChatGPT, Stable Diffusion, or similar – has captured mainstream attention in a way few could have predicted. The fruits of this innovation can be found in practically every sector, from supply chain vendors to students at university. Some herald this as the beginning of a new era; one where artificial intelligence will work alongside humans, replacing many of the mundane tasks of modern business, work and study. Others are far more tentative, believing the merits of generative AI are grossly overstated, if not outright fraudulent.

Supply Chain Lessons from Financial Markets (with Peter Cotton) - Ep 139

In an interview, Peter Cotton, Chief Data Scientist at Intech, and Joannes Vermorel, founder of Lokad, discuss probabilistic forecasting, the M6 forecasting competition, and the differences between finance and supply chain perspectives on volatility and uncertainty. They emphasize that perfect forecasts are impossible and probabilistic forecasting can help make better decisions amid volatility. Both agree on the value of simplicity and robustness in handling complex systems, whether financial markets or supply chains. They also discuss issues like P-hacking, transparency in prediction model errors, and market mechanisms for improving predictions. Vermorel highlights the cultural challenges in supply chain management, while Cotton emphasizes the importance of markets in improving overall forecasting.

The Supply Chain Scientist - Lecture 7.3

At the core of a Quantitative Supply Chain initiative, there is the Supply Chain Scientist (SCS) who executes the data preparation, the economic modeling and the KPI reporting. The smart automation of the supply chain decisions is the end-product of the work done by the SCS. The SCS takes ownership of the generated decisions. The SCS delivers human intelligence magnified through machine processing power.

Beyond Safety Stock: The Role of Probabilistic Forecasts in Supply Chain (with Sim Taylor) - Ep 138

The meaning, role, and value of probabilistic forecasting are often viewed as mysterious and impossible to grasp without a degree in data science. On the contrary, probabilistic forecasting is rather intuitive, as we discussed with our guest, Sim Taylor.

Debunking Supply Chain Terminology - Supply Chain in 3 minutes

In supply chains a sizable portion of supply chain terminology is inadequate. Good terminology should be as neutral and factual as possible, however this is far from the case in supply chain. We suggest changes to ABC analysis, service level, safety stock, seasonality, EOQ, BI and ERP, along with an explanation behind our proposed improvements.

Running a Large Scale Aviation Supply Chain at Air France Industries with Jacques Dauvergne

More than 1000 flights from nearly 200 companies are able to take-off daily thanks to the repairs and maintenance carried out by Air France Industries. If you are curious to learn how such a complex supply chain program runs and how Lokad is coordinating efforts to optimize the process, Jacques Dauvergne- Senior Vice President Supply Chain at AFI- is happy to share all the aspects and insights of the story.

Long-term Supply Chain Resilience while Firefighting (a discussion with Jay Koganti) - Ep 137

Resilience is very much this decade’s supply chain cause célèbre (and with good reason). The intrusion of constant shocks - and the inevitable firefighting that follows - has tested the resilience (and exposed the fragility) of supply chains across the globe.

Kanban - Supply Chain in 3 minutes

The Kanban method was initially implemented to improve manufacturing efficiency and reduce waste by providing a simple and visual material replenishment process so that every step of the production process would get just enough to operate smoothly without stockpiling raw materials or components.

Histories of the Future: A Discussion with Jonathon Karelse - Ep 136

Histories of the Future Milestones in the Last 100 Years of Business Forecasting, by Jonathon Karelse, charts the fascinating development of business forecasting tools, techniques and innovations over the last century.

Revima X Lokad - Projet d'Optimisation des Stocks

Interviews exclusives avec Olivier Legrand (Président de Revima) ; Brice Arias (Responsable de la chaîne d'approvisionnement de Revima, APU & Landing gear MRO) ; Sebastien Honore (Revima LDG - Buyer & Planner) ; Thomas Niel (Revima Purchasing Group) ; et Simon Schalit (Directeur des opérations chez Lokad).

Lead-time forecasting - Lecture 5.3

Lead times are a fundamental facet of most supply chain situations. Lead times can and should be forecast just like demand. Probabilistic forecasting models, dedicated to lead times, can be used. A series of techniques are presented to craft probabilistic lead time forecasts for supply chain purposes. Composing those forecasts, lead time and demand, is a cornerstone of predictive modeling in supply chain.

Problem- vs Solution-oriented Software Design in 3 minutes

Every single SKU calls for mundane daily decisions, such as moving in more stock or changing the underlying price tag. Naturally, sticking to a fully manual process for those decisions is labor intensive and companies have been adopting varied software-based automation solutions.

Bureaucracies in Supply Chains in 3 minutes

At the core, there are two fundamental problems that, almost without exception, lead to the undoing of supply chain optimization initiatives. First, a misguided thirst for control; second, bureaucracy taking precedence over reality.

Choosing the right service level in 3 minutes

The service level represents the desired probability of not getting a stock-out. The more product you stock, the lower the chances of running out of stock, but also the higher the inventory cost. Deciding on the right service level for a certain product is essentially balancing inventory costs with the cost of a stock out.

Logistics and Supply Chain at La Redoute

Patrice Fitzner decided a decade ago to translate his knowledge from the automotive industry to La Redoute, the second largest women’s clothing retailer. Patrice has been a major contributor in the creation and success of La Redoute’s ultra-modern logistics platform called Quai 30.

Why a digital aviation supply chain? Answers by Air France Industries

Exclusive interviews with Jacques Dauvergne (Senior VP Supply Chain); Fanny Kientz (VP Engine Supply Chain and Assets); Guillaume Adrien (VP Supply Chain Design and Performances); Olivier Pelloux-Prayer (VP Assets and Outsourced Repairs of Component Division); and Stephan Lise (Head of Prognos for Inventory).

The Real Beer Game (with Jes Bengtsson) - Ep 135

A mainstay of supply chain tutorials since the 1960s, The Beer Game has taught students how to visualise the oftentimes tricky coordination of upstream and downstream supply chain processes.

Supply Chain Triangle in 3 minutes

The supply chain triangle refers to the correlation between cost, cast and service in a supply chain. A business provides its customers with a certain type of service that requires both cash to produce and deliver and has a cost associated with it.

Fresh Food for Supply Chains (with Richard Lubienski)

How do the principles of supply chain forecasting apply to a business dealing with perishable stock? Are there unique supply chain challenges for companies in this space? What additional layers of complexity and randomness must this sector contend with when forecasting stock levels?

Prioritized ordering in 3 minutes

Supply chain literature most often focuses on ordering policies where each separate item is treated in complete isolation to all the other items. the decision to order more units of item A is strictly independent from the decision to order more units of item B. In contrast, the prioritized ordering policy emphasizes multi-item decisions, where each item competes for capital allocation with all the other items.

Supply Chain Persona: Stuttgart, an automotive aftermarket company - Lecture 3.4

Stuttgart is a fictitious automotive aftermarket company. They operate a network of stores delivering car repairs, car parts and car accessories. In the early 2010s, Stuttgart also started two ecommerce channels, one to buy and sell car parts, and one to buy and sell used cars.

Micro fullfilment in 3 minutes

Micro fulfillment is a strategy used by retailers to improve the efficiency of the e-commerce order-fulfillment process. The objective is to stock the fast-moving SKUs in multiple small storage facilities situated close to the end customer.

Home Segment & Supply Chain challenges at La Redoute

While pricing and promotions sound as straightforward as offering the best price and maximizing margins, the equation becomes tremendously more difficult when factoring in the enormous size of the catalog, its diversity and seasonality.

Profit from the Source (with Christian Schuh)

Christian SCHUH is a Managing Director and Senior Partner at Boston Consulting Group. With his 27-year career in procurement consulting for the automotive, engineering and defense industries, he believes that the most important factor in the success of a business now and in the future is the close relationship between a company and its suppliers.

Odd pricing in 3 minutes

Odd pricing is a pricing method aimed at maximizing profit by making micro-adjustments in pricing structure, relying on the assumption that consumers are calculation-averse and will only read the first digits of a price.

Supply Chain News on news.lokad.com

The world of Supply Chain is exceedingly opaque and there are very few places on internet nowadays where you can learn anything of value about it. While Reddit targets a young category of users and Wikipedia is bound to contain old and somewhat deprecated information, LinkedIn remains one of the only trustworthy source of information in the field, due to the experience of the professionals that are sharing their experiences.

Fashion Segment & Supply Chain challenges at La Redoute

As the second largest women’s clothing retailer, La Redoute’s teams manage a grand total of 18,000 references with a renewal rate of 70% to 80%. Pricing being the number one concern for online customers, the task of managing pricing policies for the entire catalog while maximizing margin is immensely complex if you factor in the evolution of legislation and promotional pressure.

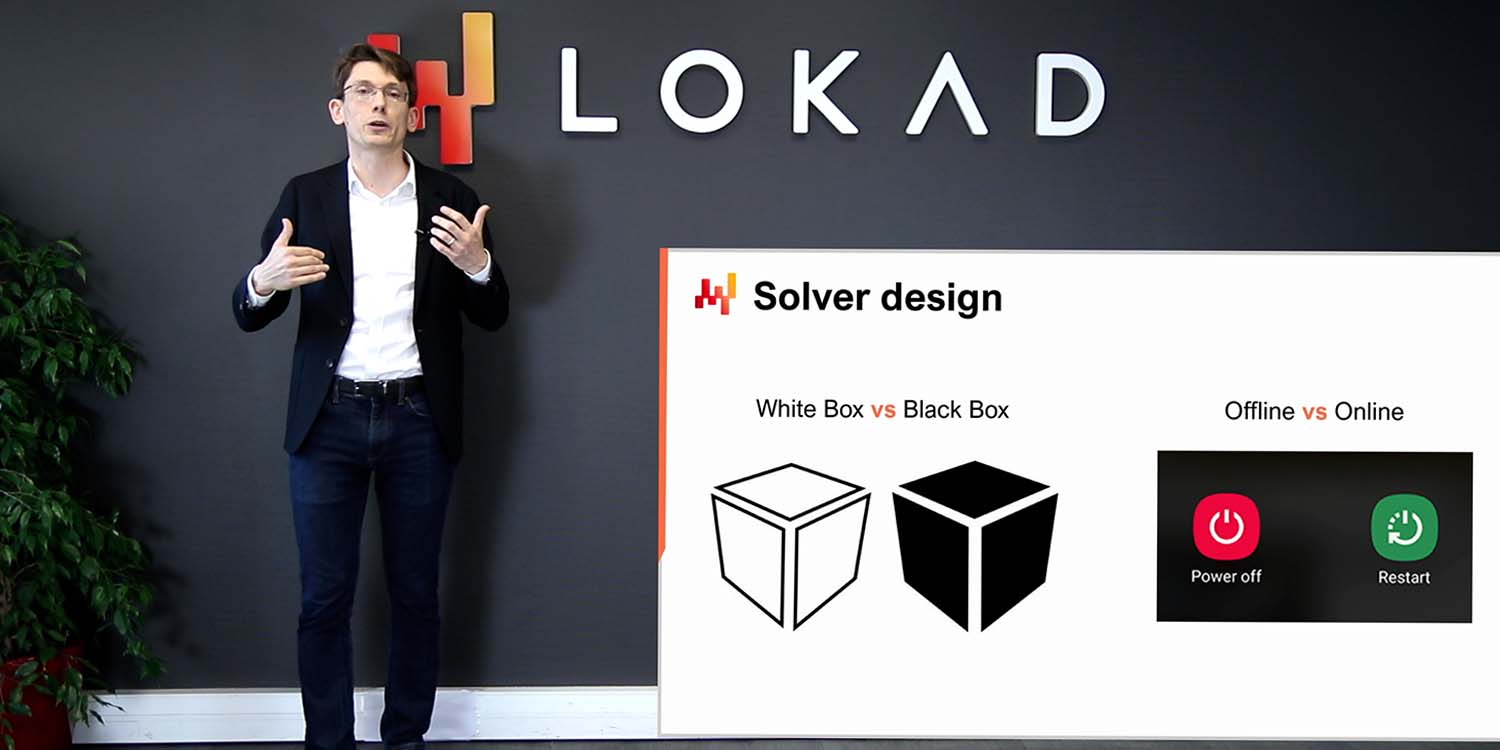

Bringing automated supply chain decisions to production - Lecture 7.2

We seek a numerical recipe to drive an entire class of mundane decisions, such as stock replenishments. Automation is essential to make supply chain a capitalistic endeavor. However, it carries substantial risks of doing damage at scale if the numerical recipe is defective.

La Redoute x Lokad - Visit of Quai 30 / What does a modern warehouse look like

As a European leader in ecommerce with a catalog of humongous size and diversity, La Redoute needed a state-of-the-art logistics platform that could handle 300,000 stocked products and process more than 3,500 orders per hour.

Digital Twins of real-world Supply Chains

Digital twin has become a buzzword in the supply chain industry, and refers to a virtual representation of a physical process. A supply chain’s digital twin is a simulation of that supply chain as a whole. In this episode, we challenge the claims that digital twins are delivering on their promise of conducting accurate simulation and what-if modeling to immediately see the impact of various supply chain decisions.

Co-packing in 3 minutes

Co-packing is the process of packing products together to create a shelf-ready product for the retailer to sell.Services from specialized co-packing providers can be quite extensive, from designing the packaging (whether that be blister packs, shrink wrapping, liquid dispensing packaging, etc.), to laminating, folding flyers, printing and attaching labels or barcodes to products, dry/liquid filling, or kitting.

The Strategy-driven Supply Chain (with Bram Desmet)

In this episode, we are honored to welcome Bram Desmet, professor, keynote speaker and founder of the Strategy-Driven Supply Chain Institute to discuss the profound link between supply chain and a company’s strategy.

La Redoute x Lokad - Optimisation Prédictive via l'Intelligence Artificielle

La Redoute, the second largest women's clothing retailer, chose Lokad to drive transformation around predictive optimization. The goal of this collaboration was to use artificial intelligence to better manage the match between pricing, sales performance, and inventory.

EOQ (Economic Order Quantity) in 3 minutes

The economic order quantity is essentially a trade-off between the ordering cost and inventory holding cost. If the company’s ordering costs or product demand increases, the order quantity increases. Similarly, if the holding cost increases, the order quantity decreases.

Getting started with a quantitative supply chain initiative - Lecture 7.1

Conducting a successful predictive optimization of a supply chain is a mix of soft and hard problems Unfortunately, it is not possible to take those aspects apart. The soft and hard facets are deeply entangled. Usually, this entanglement collides frontally with the division of work as defined by the organigram of the company.

Emerging algorithmic paradigms for supply chain optimization (with David Simchi-Levi)

In this episode we are discussing paradigms that are now emerging for optimization and learning in Supply Chain, and we are joined by Prof. David Simchi-Levi,author of over 300 publications, in which a common topic is algorithmic paradigms for supply chain.

KPI (key performance indicator) in 3 minutes

KPIs stands for Key Performance Indicators and are extensively used in supply chain management to measure how a business is performing in a specific area to indicate how effectively the company is achieving its business targets.

Stockouts in 3 minutes

A stockout happens when the inventory is exhausted. Stockouts are usually treated as problems to be fixed, and many inventory methods, such as safety stocks, have been devised to control the frequency associated with those events.

Styling Prices for Retail in 3 minutes

Better price tag design can significantly manipulate demand to increase the company’s profit. The price should be displayed in small size, on the bottom left of the label for best results as that makes the price seem as small as possible to the consumer.

What Went Wrong at Peloton - Supply Chain in Focus

In an economy stricken by a pandemic, Peloton quickly found itself rising to the top of the connected-fitness food chain. Two years later, thousands of employees are getting fired and Peloton is considering a potential sale to other corporations.

Competitive pricing in 3 minutes

A competitive pricing strategy focuses on matching your price with your competitors based on the assumption that the market has already defined the right price for a product.

Pricing strategies in 3 minutes

Prices represent a trade-off between short-term and long-term strategies, profitability and market share as well as levels of cash flow. A company sets its prices with different objectives in mind, such as profitability, cash flow or growth.

Prices and stocks optimization at Mister Auto

French car parts distributor Mister Auto has choosen Lokad for both its inventory optimization and its pricing optimization. As the European automotive aftermarket includes hundreds of thousands of part references, stocking all parts at all time isn't economically viable. Moreover, minimal order quantities (MOQs) further complicates the fulfillement of the demand, typically both intermittent and erratic for most parts. Finally, the European automative aftermarket is fiercely competitive, requiring constant pricing readjustments to stay ahead of the competition.

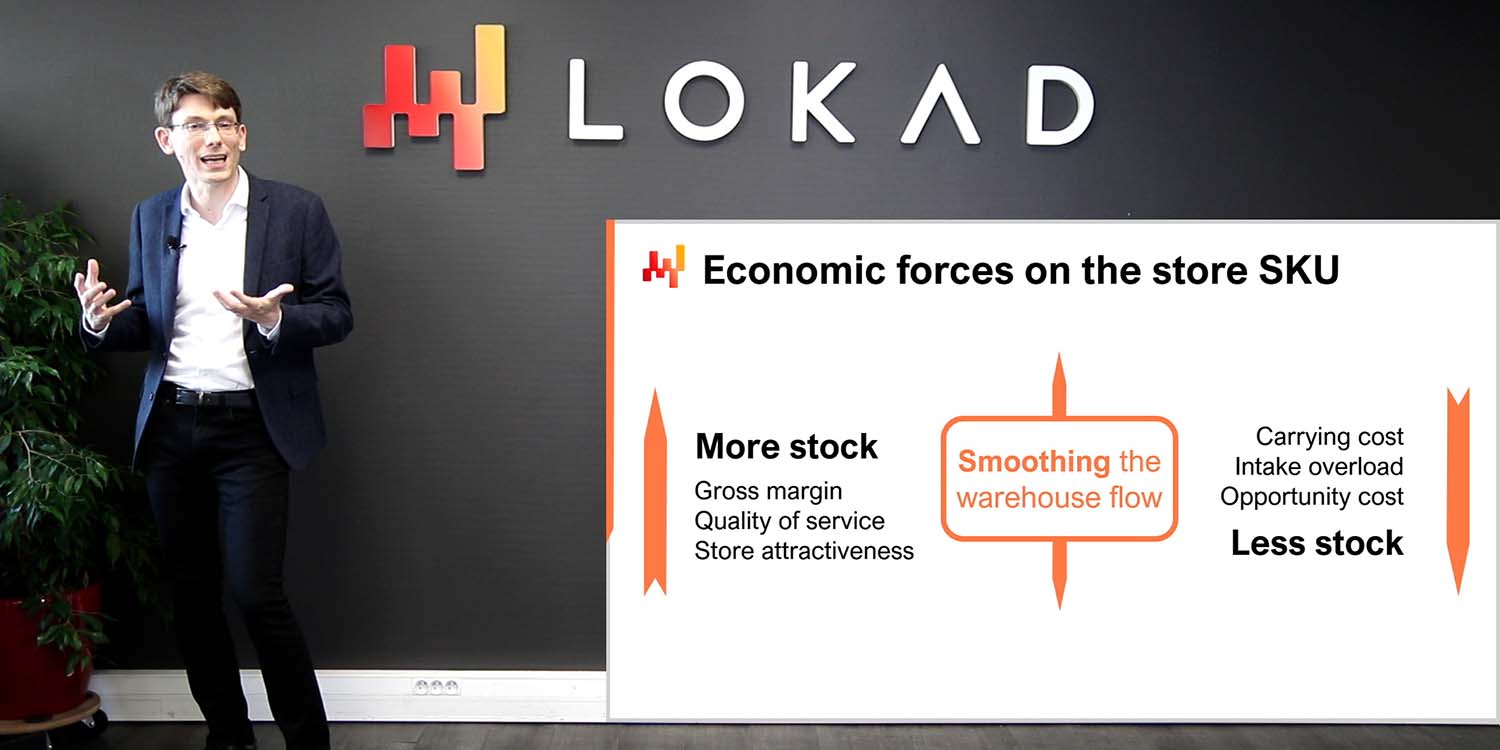

Retail stock allocation with probabilistic forecasts - Lecture 6.1

Supply chain decisions require risk-adjusted economic assessments. Converting probabilistic forecasts into economic assessments is nontrivial and require dedicated tooling. However, the resulting economic prioritization, illustrated by stock allocations, proves itself more powerful than traditional techniques. We start with the retail stock allocation challenge. In a 2-echelon network that includes both a distribution center (DC) and multiple stores, we need to decide how to allocate the stock of the DC to the stores, knowing that all stores compete for the same stock.

Retail Channel Promotions in 3 minutes

A promotion is an activity where a type of marketing communication is used to inform a target audience of a particular product or service, for example that it now has a discounted price. Companies engage in promotions to boost sales and revenue, but also to disrupt customer behavior in their favor. When a company runs a promotion, communication must put that forward to the target audience to ensure the desired uplift in demand for that product or their store.

Lean Supply Chains in 3 minutes

What does it mean for a supply chain to be lean? In manufacturing, lean describes the method that maximizes productivity while simultaneously minimizing waste. A lean Supply Chain also aims to eliminate waste through better inventory control and streamlining all supply chain processes, although supply chains are by nature very complex and frequently see conflicting incentives and points of view.

Shipping Containers in 3 minutes

The global use of containers for transportation has resulted in major cost reductions, boosting supply chain efficiency. One of the container’s key advantages is its global ‘Standardization’ of its dimensions regardless of location. Cargo is shipped in containers that are either exactly the same or a multiple of the standard unit of size.

Feedback Loops and Machine Learning in Supply Chain

Advancements in technology, such as machine learning and AI, have provoked the question on how to best apply this technology in order to maximize the supply chain performance. Can machine learning be applied in a way that, by providing it with more and more forecasting data, increasingly better forecasts are being produced through complex feedback loops?

Data Aggregation and Forecasting

When it comes to demand forecasting, there is an incredible diversity of methods and levels of data aggregation that are used. Some companies forecast on a daily basis whilst others on weekly, monthly, quarterly or yearly basis. Some forecast at the SKU level whilst others at the category level. How does one choose the right level of data aggregation?

Cross-docking in 3 minutes

Cross-docking, is a logistics method of having goods enter and exit the facility without ever being put in storage. Whilst this method removes loading and pick up operations from warehousing staff, it does so at the expense of the flexibility offered by having the goods stored at the warehouse. Not holding stock certainly comes with many attractive advantages, but also drawbacks such as worse deals with suppliers and a reduction of service to the customers.

Time Series for Supply Chain in 3 minutes

Time series are one of the most basic and versatile mathematical tools used in business to support statistical models and consist of a series of data points linked to a particular point in time. Time series are frequently used to model anything from the evolution of a company’s sales, product prices and lead times on a yearly, monthly, daily or even hourly basis.

Probabilistic Forecasting for Supply Chain - Lecture 5.2

A forecast is said to be probabilistic, instead of deterministic, if it contains a set of probabilities associated with all possible future outcomes, instead of pinpointing one particular outcome as the forecast.

Starting a Career in Supply Chain (with Lora Cecere)

In this episode, we are honored to welcome Lora Cecere, the founder of Supply Chain Insights and expert industry analyst with over 35 years of diverse experience in the field to discuss Starting a Career in Supply Chain and the attractive opportunities it brings.

FMCG (Fast Moving Consumer Goods) Supply Chain in 3 minutes

The FMCG industry is one of the oldest in our civilization. Packaging and processing technologies have continuously been evolving, but other supply chain practices such as optimizing recipe composition, are still managed through trial and error at best.

Hard Luxury Supply Chain in 3 minutes

The supply chain for hard luxury (high end jewellery and watches) is defined by unique challenges. Unlike how most products are otherwise generally mass produced, each piece of hard luxury is either unique or part of a limited collection. Even though these luxury goods are timeless in their value and appreciation, there is still an expectation of novelty from the customer. This sparse demand, combined with a continuous push for novelty, are the main challenges in the supply chain in hard luxury.

Structured predictive modeling for Supply Chain - Lecture 5.1

Differentiable Programming (DP) is a generative paradigm used to engineer a broad class of statistical models, which happen to be excellently suited for predictive supply chain challenges.

ERP (Enterprise Resource Planning) in 3 minutes

ERP (Enterprise Resource Planning) refers to a class of enterprise software that supports and keeps track of the routine operations for a company, and tracks its resources, such as cash flow, raw materials, work in progress, end products, client orders, purchase orders, and payroll.

Dynamic Supply Chains (with Dr. John Gattorna)

In this episode we are joined by Dr. John Gattorna, one of the most respected supply chain thought leaders in the world and whose work has influenced many of today’s leading corporations. We discuss the importance of a supply chain strategy that aligns with a customer first approach, the evolution (or devolution) of supply chains in the last century, and whether software advancements that were designed to speed up internal processes have also contributed to slowing them down.

Spare Parts for Supply Chain in 3 minutes

The main goal in the spare parts industry is to minimize the downtime of your valuable assets such as aircrafts, vessels, oil rigs, wind turbines, generators, manufacturing equipment and heavy machinery. Whenever an asset needs repair or maintenance, the piece of machinery undergoes a full stop which is a highly costly scenario.

No1 at the SKU-level in the M5 forecasting competition - Lecture 5.0

In 2020, a team at Lokad achieved No5 over 909 competing teams at the M5, a worldwide forecasting competition. However, at the SKU aggregation level, those forecasts landed No1. Demand forecasting is of primary importance for supply chain.

Fashion Supply Chain in 3 minutes

Fashion is driven by novelty. It constitutes the core of fashion, as well as its key challenge. Fashion brands are continuously producing and designing new collections that are driven by current trends and the upcoming season.

Cybersecurity for supply chain - Lecture 4.7

Cybercrime is on the rise. Ransomware is a booming business. Due to their physically distributed nature, supply chains are particularly exposed. Moreover, ambient complexity is a fertile ground for computer security woes.

Uncertainty in Supply Chain, Lessons from the M5 Competition

Joannes Vermorel outlines a short series of lessons to supply chain practitioners from the M5 Forecasting Competition. The M5 did offer a unique opportunity to do a reality check on the claims of the majority of the supply chain software vendors. This talk was given as part of the M5 Conference.

Copycats in Supply Chain

The supply chain industry is driven by buzzwords. A decade ago, cloud computing and probabilistic forecasts were not associated with the supply chain industry. Now (2021) it is the talk of the industry, alongside AI,blockchain and machine learning. Vendors are quick to keep up to date and adapt with these trends.

Estelle Vermorel's interview with BFM Business

Lokad's Co-founder, Estelle Vermorel, was a guest on the Focus PME show hosted by Vincent TOURAINE on BFM Business.

Software engineering for supply chain - Lecture 4.6

Taming complexity and chaos is the cornerstone of software engineering. Considering that supply chains are both complex and chaotic, it shouldn’t come as too much of a surprise that most of the enterprise software woes faced by supply chains boil down to bad software engineering.

Forecasting Accuracy for Supply Chain in 3 minutes

Forecasting is the practice of analyzing historical data to predict anticipated conditions in the future and is at the core of supply chains. Naturally, increasing their accuracy became highly sought after. But what factors affect forecasting accuracy?

Forecasting Accuracy in dollars instead of percentages

The supply chain industry has for decades been in a constant chase of better accuracy of forecasts in a desperate attempt to predict the future. In fact, forecasting is so common in supply chain practices that every large company has its own division dedicated to improving their forecasting accuracy.

Languages and compilers for supply chain - Lecture 4.5

The majority of supply chains are still run through spreadsheets (i.e. Excel), while enterprise systems have been in place for one, two, sometimes three, decades - supposedly to replace them. Indeed, spreadsheets offer accessible programmatic expressiveness, while those systems generally do not.

Numerical Forecasting for Supply Chain in 3 minutes

At its core, the practice of numerical forecasting is about using a scientific approach to define a future anticipation based on previous historical data. When we produce, or transport goods, there are delays involved in every process. This means that what you decide today ultimately reflects an anticipated condition about the future.

The Bullwhip Effect in 3 minutes

The Bullwhip Effect is a well known supply chain distortion, commonly described as a problem that must be avoided. At Lokad, however, we would argue that the bullwhip effect is a phenomenon that naturally occurs in supply chains, and minimizing it is not necessarily advantageous for your business.

Supply chain persona: San Jose, homeware ecommerce - Lecture 3.3

San Jose is a fictitious ecommerce that distributes a variety of home furnishing and accessories. They operate their own online marketplace. Their private brand competes with external brands, both internally and externally. In order to remain competitive with larger and lower priced actors, San Jose’s supply chain attempts to deliver a high quality of service that takes many forms, well beyond the timely delivery of the goods ordered.

Estelle Vermorel's interview with Demain Entreprendre

Lokad's Co-founder, Estelle Vermorel, was a guest on the "Demain Entreprendre" show hosted by Jerome Libeskind on Demain TV.

Dusting the ERP market (with Fabien Pinkaers)

The Enterprise Resource Planning (ERP) market has become almost overgrown with the variety of software solutions offered. Several tech giants are dominating the market, such as SAP, Oracle, Microsoft, and now also Odoo which has become a key player. In this episode, we are thrilled to be joined by Odoo's founder, Fabien Pinckaers, to explore how the ERP market has been both developing in the last decades, but also stagnating.

Service level in 3 minutes

In supply chain, the service level is a measure of quality of service. However, the definition of service level has not been fully agreed on. Some use it as the percentage of total demand covered in units of product, others define it as the percentage of orders fulfilled.

Machine learning for supply chain - Lecture 4.4

Forecasts are irreducible in supply chain as every decision (purchasing, producing, stocking, etc.) reflect an anticipation of future events. Statistical learning and machine learning have largely superseded the classic ‘forecasting’ field, both from a theoretical and from a practical perspective. We will attempt to understand what a data-driven anticipation of the future even means from a modern ‘learning’ perspective.

Mathematical optimization for supply chain - Lecture 4.3

Mathematical optimization is the process of minimizing a mathematical function. Nearly all the modern statistical learning techniques - i.e. forecasting if we adopt a supply chain perspective - rely on mathematical optimization at their core. Moreover, once the forecasts are established, identifying the most profitable decisions also happen to rely, at its core, on mathematical optimization. Supply chain problems frequently involve many variables. They are also usually stochastic in nature. Mathematical optimization is a cornerstone of a modern supply chain practice.

Blockchains for supply chain - Lecture 4.21